Essential Guide To Hydraulic Tubing: Benefits, Types, And Maintenance

-

2023-05-22

2023-05-22

-

Hydraulic tubing plays a vital role in various industries, enabling the transmission of fluid power for a wide range of applications. This comprehensive guide aims to explore the benefits, types, and maintenance practices associated with hydraulic tubing.

By understanding the advantages of hydraulic tubing, the different types available, and implementing proper maintenance procedures, businesses can optimize their hydraulic systems’ performance and ensure longevity.

Let’s dive deeper into the world of hydraulic tubing and discover why it is a crucial component in numerous industries.

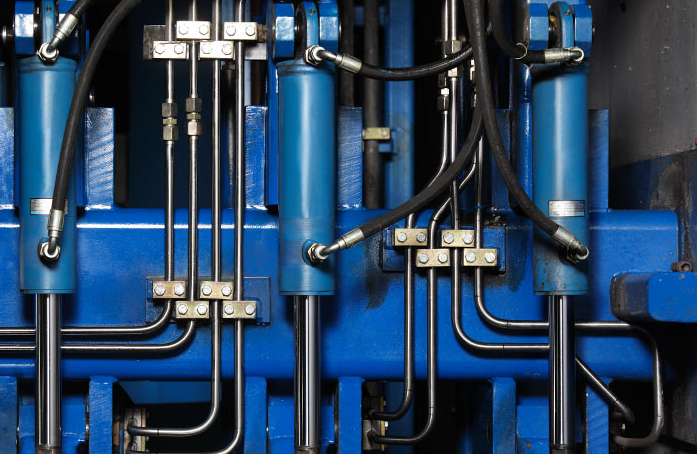

What Is Hydraulic Tubing?

It is an important component in the hydraulics system. Hydraulic tubing is a flexible, transparent tube that carries high-pressure hydraulic fluids. It is used in the steering, braking, and suspension systems of vehicles. Hydraulic tubing is made up of different types of materials like rubber, plastic, metal, and fiberglass.

How does the hydraulic tubing work?

Hydraulic tubing works by transmitting hydraulic fluid under pressure to various components within a hydraulic system. The basic principle behind hydraulic systems is Pascal’s law, which states that when pressure is applied to a fluid in an enclosed system, the pressure is transmitted equally in all directions.

The flexibility of hydraulic tubing allows it to be routed in complex paths, accommodating the layout and design requirements of the system. The tubing is designed to withstand high pressures and temperature variations without leaking or failing. The choice of tubing material depends on the specific application and the compatibility of the material with the hydraulic fluid being used.

Benefits Of Hydraulic Tubing:

Hydraulic tubing offers numerous benefits that make it an ideal choice for fluid power transmission. Here are some of the key benefits of hydraulic tubing:

- Firstly, hydraulic tubing provides high strength and durability, allowing it to withstand extreme pressures and temperature fluctuations. This reliability ensures smooth and efficient operation, reducing downtime and increasing productivity.

- Additionally, hydraulic tubing offers excellent corrosion resistance, making it suitable for various environments, including harsh conditions and corrosive substances.

- Another advantage of hydraulic tubing is its versatility. It can be easily customized to suit specific applications, with various sizes, shapes, and materials available. This flexibility enables hydraulic tubing to be used in a wide range of industries, such as construction, manufacturing, agriculture, and automotive.

Types Of Hydraulic Tubing:

Hydraulic tubing comes in different types, each with its own unique properties and applications. The most commonly used types include steel, stainless steel, and thermoplastic tubing.

1) Steel Tubing:

Steel tubing is renowned for its exceptional strength and durability, making it suitable for high-pressure applications. It is commonly used in heavy machinery, hydraulic cylinders, and industrial equipment.

Steel tubing is available in various grades, such as carbon steel and alloy steel, offering different levels of strength and resistance to corrosion.

In Global Precision Steel Tube, there are many tubes used in hydraulic systems, such as EN 10305 Galvanized Hydraulic Seamless Steel Tube. Its outer diameter is 4-120mm, WT is 0.5-10mm; the length is fixed at 6 meters, and it can also be determined according to customer needs.

This pipe for hydraulic tubing adopts galvanized treatment and cold-drawn treatment. These manufacturing processes make it more durable and resistant to corrosion.

It has good strength and rigidity, which makes it suitable for use in many applications. The product is easy to process, allowing it to be cut and welded into various shapes.

2) Stainless Steel Tubing:

Stainless steel tubing possesses excellent corrosion resistance, making it ideal for applications involving chemicals or exposure to moisture.

It is commonly used in the food and beverage industry, pharmaceuticals, and marine environments. Stainless steel tubing is available in different grades, including 304 and 316, each with its own corrosion resistance properties.

3) Thermoplastic Tubing:

Thermoplastic tubing is lightweight, flexible, and resistant to chemicals and abrasion. It is commonly used in applications where weight reduction is critical, such as aerospace and automotive industries. Thermoplastic tubing offers excellent flexibility, allowing for easy installation in tight spaces.

Global Precision Steel Tube is a professional manufacturer of seamless precision steel tubes. They can provide you with the high-quality tubes and relative components and accessories you need. You can get samples from them to determine their quality.

Maintenance Of Hydraulic Tubing:

Proper maintenance is essential to ensure the optimal performance and longevity of hydraulic tubing systems. Neglecting maintenance can lead to costly repairs, downtime, and safety hazards. Here are some essential maintenance practices to follow:

Regular Inspection:

Perform routine inspections to identify signs of wear, leaks, or damage in hydraulic tubing. Look for any signs of corrosion, abrasion, or loose fittings. Early detection can prevent major failures and extend the lifespan of the system.

Cleanliness:

Keep the hydraulic tubing system clean of dirt, debris, and contaminants. Regularly clean the tubing and surrounding areas to prevent blockages and maintain efficient flow.

Lubrication:

Proper lubrication is crucial for the smooth operation of hydraulic tubing. Apply lubricants to fittings and connectors as recommended by the manufacturer to reduce friction and prevent premature wear.

Tighten Fittings:

Check and tighten fittings regularly to prevent leaks and maintain a secure connection. Loose fittings can result in fluid loss and system inefficiencies.

Replace Worn-out Components:

Monitor the condition of hydraulic tubing components, such as seals, O-rings, and hoses. Replace any worn-out or damaged parts promptly to avoid system failure.

Fluid Quality:

Monitor the quality and condition of hydraulic fluid regularly. Contaminated or degraded fluid can damage the tubing and other components. Maintain proper fluid levels and follow recommended fluid change intervals.

Final words:

It is a vital component in various industries, offering numerous benefits and ensuring the efficient transmission of fluid power.

By understanding the benefits, and different types, and implementing proper maintenance practices, businesses can optimize their hydraulic systems’ performance, reduce downtime, and increase productivity.

Embrace the essential guide provided here to harness the full potential of hydraulic tubing and achieve reliable and efficient fluid power transmission in your operations.