High-Pressure Precision Seamless SAE J524 Hydraulic Tubing

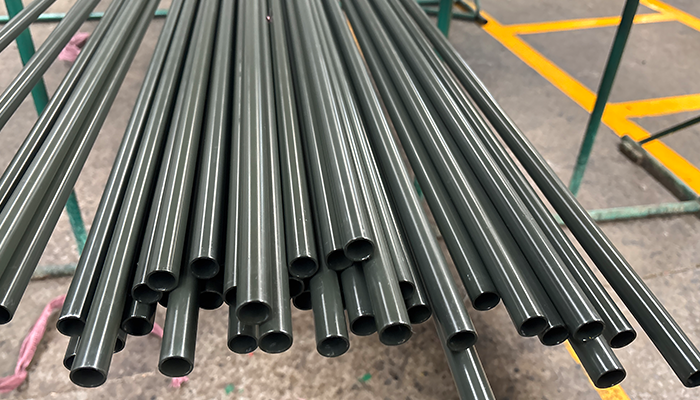

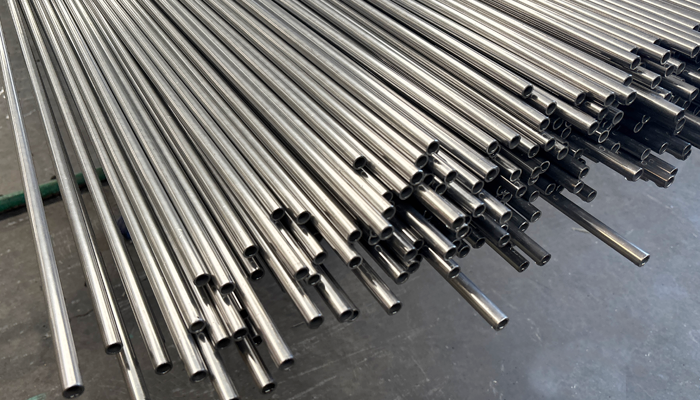

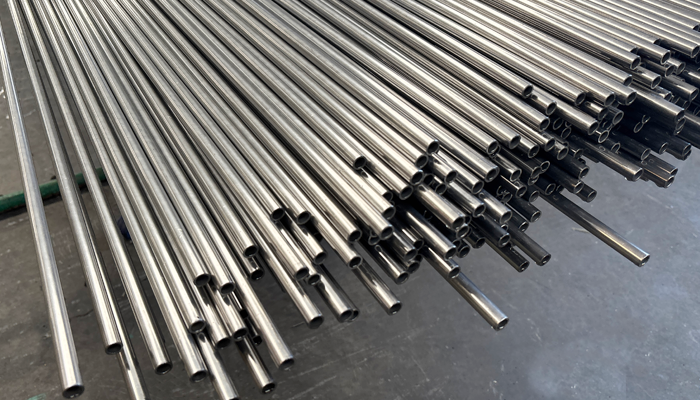

High-Pressure Precision Seamless SAE J524 Hydraulic Tubing is a premium-grade steel tube designed for high-pressure fluid systems. Conforming to the SAE J524 standard, it features a seamless construction that ensures superior performance in demanding hydraulic and fluid power applications. This tube offers excellent resistance to corrosion, high mechanical strength, and is ideal for systems requiring high-pressure fluid transfer, such as in construction machinery, automotive applications, and industrial systems.

Product Advantages

- SAE J524: Specifies the requirements for seamless cold-drawn low-carbon steel tubing used in hydraulic and fluid power systems.

- ISO 17165-1: Hydraulic fluid power — Steel tubes for use in hydraulic systems.

- ASTM A179: Standard specification for seamless cold-drawn low-carbon steel heat-exchanger and condenser tubes.

- EN 10305: Steel tubes for precision applications, suitable for fluid power systems.

.png)

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

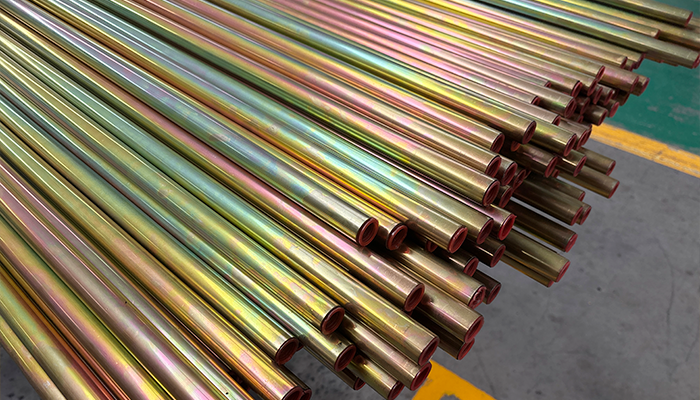

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

- High-Pressure Resistance: Designed to withstand the demands of high-pressure fluid applications, ensuring reliability and safety in critical systems.

- Seamless Construction: Manufactured without welds to provide a smooth inner surface, enhancing fluid flow and reducing the risk of failure.

- Precision Engineering: Cold-drawn to tight tolerances for superior dimensional accuracy and surface finish.

- Corrosion Resistance: Available with various surface treatments, such as phosphating or galvanization, to protect against corrosion and extend tube life.

- Customizable Sizes: Offered in a wide range of sizes, including different outer diameters and wall thicknesses, to meet specific system requirements.

| Parameter | Details |

| Outer Diameter (OD) | 6mm to 120mm |

| Wall Thickness (WT) | 0.5mm-10mm |

| Length | Standard length of 6 meters, customizable upon request |

| Steel Grades | E235 ( ST35、ST37.4 ),E255 ( ST45 ), E355 ( ST52 )

|

| Surface Finish | Bright annealed, phosphated, or galvanized for corrosion resistance |

| Delivery Condition | Cold-drawn, seamless, and annealed for stress relief |

| Shape | Round |

| Maximum Working Pressure | Varies depending on diameter and wall thickness |

- Raw Material Selection: High-quality low-carbon steel billets are selected based on the specifications of SAE J524.

- Cold Drawing: Steel is drawn through a die to reduce its diameter and achieve the required wall thickness. This process ensures precise dimensional accuracy and excellent surface finish.

- Annealing: The tube is heat-treated to relieve internal stresses, improving its mechanical properties and reducing the risk of brittleness.

- Surface Treatment: Tubes are cleaned and may undergo surface treatments such as phosphating or galvanization to enhance corrosion resistance.

- Inspection and Testing: Each batch of tubes is tested for dimensional accuracy, strength, pressure resistance, and corrosion resistance to meet SAE J524 standards.

Applications

- Hydraulic Systems: SAE J524 hydraulic tubing is ideal for high-pressure fluid transfer in construction equipment, agricultural machinery, and industrial systems.

- Automotive Applications: Used in automotive systems such as fuel lines, brake lines, and power steering systems, where high pressure and precision are critical.

- Pneumatic Systems: Perfect for fluid power applications in industries like manufacturing, aerospace, and mining.

- Heavy Machinery: Employed in heavy-duty equipment and machinery for transferring fluids under high pressure and ensuring system integrity.

This product description, featuring the key specifications and applications of High-Pressure Precision Seamless SAE J524 Hydraulic Tubing, would be well-suited for product listings or marketing materials. Let me know if you need any further modifications or additional information!