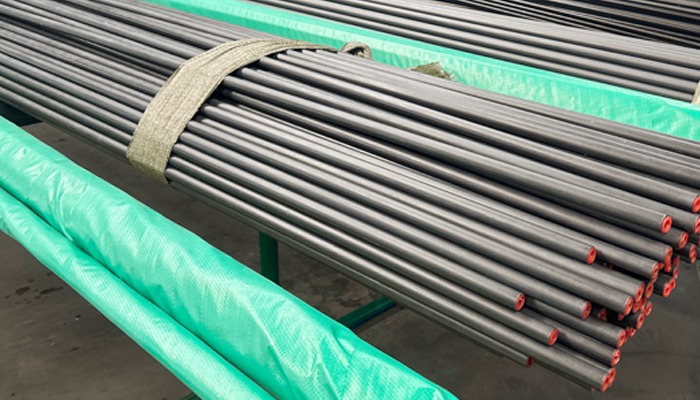

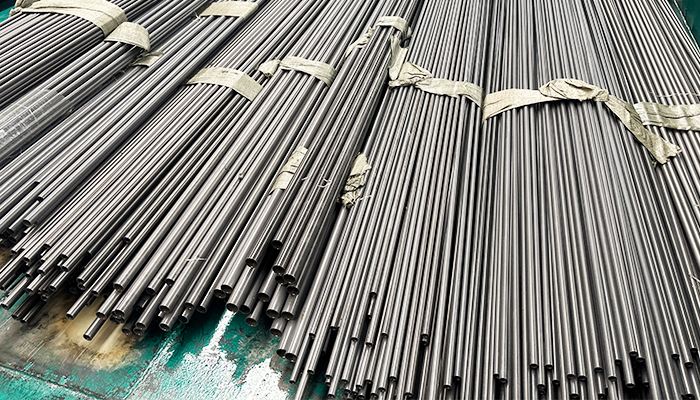

HPL Tubes with Corrosion-Resistant Surface Finishes

Product Description

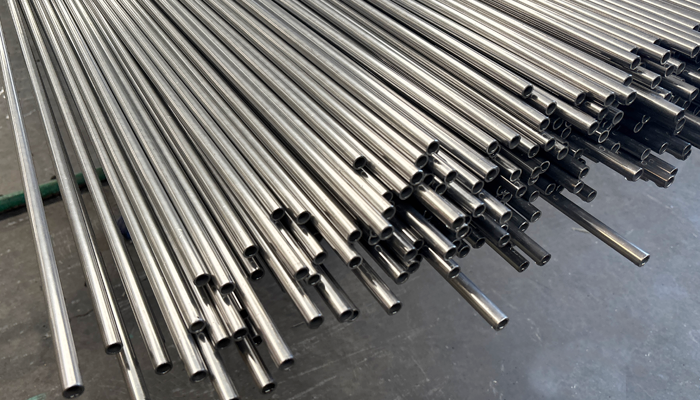

HPL Tubes (High-Pressure Laminated Tubes) are engineered for demanding applications requiring exceptional strength, durability, and precision. These tubes are made using advanced high-pressure laminating technology, combining multiple layers of durable materials to ensure excellent mechanical performance, superior corrosion resistance, and long-lasting reliability.

Product Advantages

HPL Tubes are designed to meet the stringent requirements of industries like aerospace, oil and gas, chemical processing, and heavy machinery, where high-pressure resistance and dimensional accuracy are crucial.

Dimension

| OD | Thickness(m m) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

- High-Pressure Resistance: Manufactured to withstand extreme pressures in challenging environments.

- Durable Construction: Built with high-quality materials for exceptional mechanical and chemical resistance.

- Precision Engineering: Offers excellent dimensional accuracy for seamless integration into complex systems.

- Corrosion Protection: Resistant to rust, chemical corrosion, and environmental wear.

- Customizable Sizes: Available in a variety of diameters, wall thicknesses, and lengths to suit specific project requirements.

Applications

- Aerospace Industry: Used in hydraulic systems and fluid transmission for aircraft and spacecraft.

- Oil and Gas: Ideal for high-pressure pipelines and equipment in exploration and refining processes.

- Chemical Processing: Handles aggressive chemicals and high-pressure conditions in processing plants.

- Heavy Machinery: Provides reliable hydraulic solutions for industrial and construction equipment.

- Power Generation: Used in turbines and energy systems requiring precision and durability.

Why Choose HPL Tubes?

- Premium Quality Materials: Made from robust and reliable materials for long-lasting performance.

- Precision Manufacturing: Produced using advanced technologies to ensure strict tolerances and high-quality finishes.

- Industry Standards Compliance: Conforms to international standards such as ASTM, EN, and ISO for guaranteed reliability.

- Wide Range of Applications: Perfect for industries requiring high-pressure and high-performance solutions.