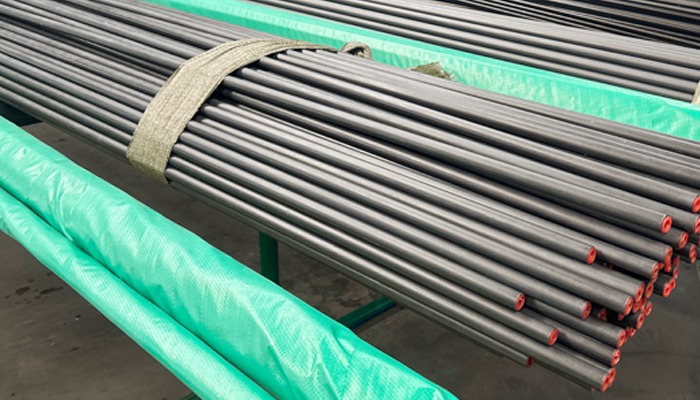

Din EN 10305 Seamless Precision Steel Tubes

DIN EN 10305 Seamless Precision Steel Tubes are high-quality tubes designed for a variety of industrial applications, particularly in hydraulic, automotive, and mechanical systems. These tubes are manufactured using advanced precision techniques to ensure high dimensional accuracy, excellent mechanical properties, and smooth surfaces, making them ideal for high-pressure and fluid transfer applications.

Product Advantages

The tubes are made from high-grade carbon steel, which offers excellent tensile strength, weldability, and machinability. The material complies with the EN 10305 standard, which ensures its suitability for precision applications, offering consistent quality and performance.

International Standards:

- DIN EN 10305: European standard for seamless precision steel tubes, primarily used in hydraulic and mechanical systems.

- EN 10305-1: Specifies requirements for cold drawn precision steel tubes used in various industries.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

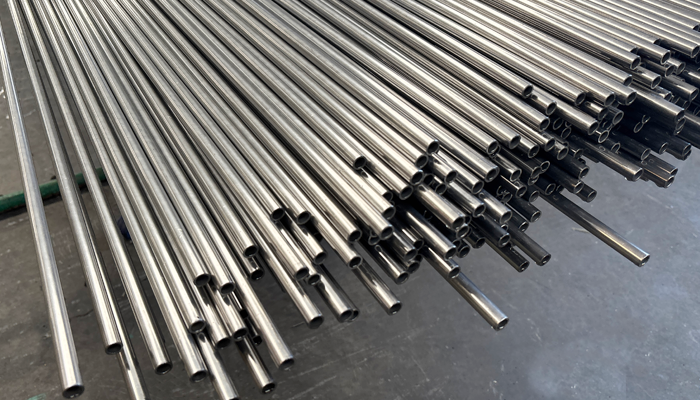

- Precision: The seamless manufacturing process ensures high precision in both dimensions and wall thickness, making these tubes suitable for critical applications requiring tight tolerances.

- Strength: Made from high-quality carbon steel, these tubes offer excellent tensile strength, making them ideal for high-pressure systems.

- Seamless Design: The seamless nature of these tubes eliminates the potential weak points caused by welding, ensuring greater reliability and durability in high-pressure applications.

- Smooth Surface: The cold drawn process ensures smooth inner and outer surfaces, minimizing fluid resistance and improving flow efficiency.

Surface Treatment:

-

-

- Standard Coating: The tubes typically come with a protective anti-corrosion oil coating on the surface to prevent rust during storage and transportation.

- Additional Treatments: For specific applications, additional surface treatments such as acid pickling, phosphating, or passivation can be applied to improve corrosion resistance.

-

| Specification | Details |

| Material | High-Grade Carbon Steel |

| Standard | DIN EN 10305-1, EN 10305-4 |

| Delivery Condition | +N (Normalized in controlled atmosphere) |

| Surface Protection | Anti-corrosion oil coating, Plastic end caps (standard protection) |

Dimensions:

| Dimension Range | Details |

| Outer Diameter (OD) | 4 mm to 120 mm |

| Wall Thickness (WT) | 0.5 mm to 10 mm |

| Length | Standard 6 meters or customized lengths |

- Piercing: Initially, solid steel billets are pierced to create hollow tubes.

- Pickling: The tubes are pickled to remove impurities, rust, and oxide scale from the surface.

- Phosphating: This process enhances the corrosion resistance and prepares the surface for further processing.

- Cold Drawing: The tubes are drawn through dies to achieve the desired diameter and wall thickness while improving the mechanical properties such as tensile strength and hardness.

- Annealing: The tubes undergo an annealing process to relieve internal stresses generated during the drawing process.

Applications

- Hydraulic Systems: Used in hydraulic cylinders, pumps, and power transmission systems where high-pressure resistance and precise dimensions are required.

- Automotive Industry: Utilized in automotive hydraulic lines, brake systems, and fuel injection systems.

- Mechanical Engineering: Ideal for structural and fluid transport applications in various mechanical systems.

- Pressure Systems: Widely used in pressure-bearing applications across industries like petrochemical, aerospace, and manufacturing.