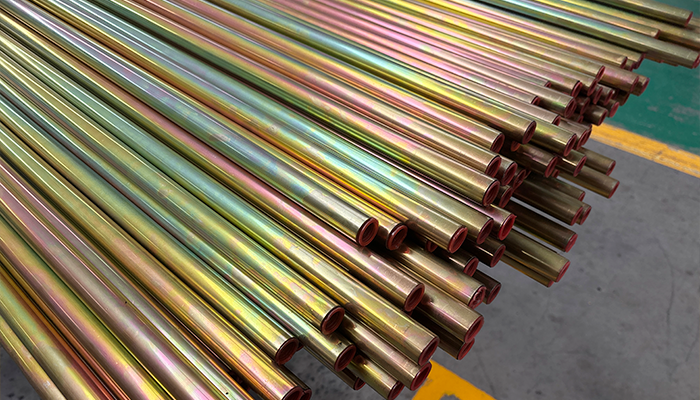

Din 2391/C St37.4 Cold Drawn Seamless Carbon Steel Pipe

The Din 2391/C St37.4 Cold Drawn Seamless Carbon Steel Pipe is a high-quality, precision-made pipe designed for various industrial applications. Known for its excellent mechanical properties and dimensional accuracy, it’s a reliable choice for high-pressure systems.

Product Advantages

- Made from St37.4 carbon steel, this material offers good ductility, weldability, and strength, ideal for handling internal and external pressures. It also ensures easy processing and high-quality performance.

International Standards

Complies with DIN 2391/C, EN 10305-4 and EN 10305-1, , meeting international quality standards for seamless steel pipes used in hydraulic systems and high-pressure applications.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

-

- High Precision: Cold drawn to ensure consistent outer diameter and wall thickness, making it easy to integrate into complex systems.

- Strong: Built to withstand high pressures, thanks to St37.4 carbon steel.

- Smooth Surface: Minimizes friction for fluid flow and enhances corrosion resistance with optional treatments.

- Seamless: Ensures no weak points, reducing the risk of leaks and increasing reliability.

Surface

The pipe is coated with anti-rust oil to prevent corrosion during storage and transport. Optional surface treatments like pickling, phosphating, or passivation can be applied for better corrosion resistance.

| Specification | Details |

| Steel Grade | St37.4 |

| Standards | DIN 2391/C, EN 10305-4, EN 10305-1 |

| Delivery State | +N (Normalized) |

| Protection | Anti-rust oil coating, plastic end caps |

Dimensions

| Dimension | Range |

| Outer Diameter (OD) | 4 – 120 mm |

| Wall Thickness (WT) | 0.5 – 10 mm |

| Length | 6 meters (custom lengths available) |

- Piercing: Steel billets are pierced to form hollow tubes.

- Pickling: Removes rust and impurities.

- Phosphating: Enhances corrosion resistance.

- Cold Drawing: Reduces pipe size and improves strength and precision.

- Annealing: Relieves internal stress and maintains pipe integrity.

Applications

- Automotive: Used in brake lines, fuel injection systems, and other hydraulic components.

- Construction Machinery: In hydraulic cylinders and piping for heavy-duty machines.

- Railway: For braking systems and suspension components.

- Shipbuilding: Hydraulic systems on ships, providing strength and corrosion resistance.

- General Hydraulic Systems: Reliable for fluid transport in various industries.