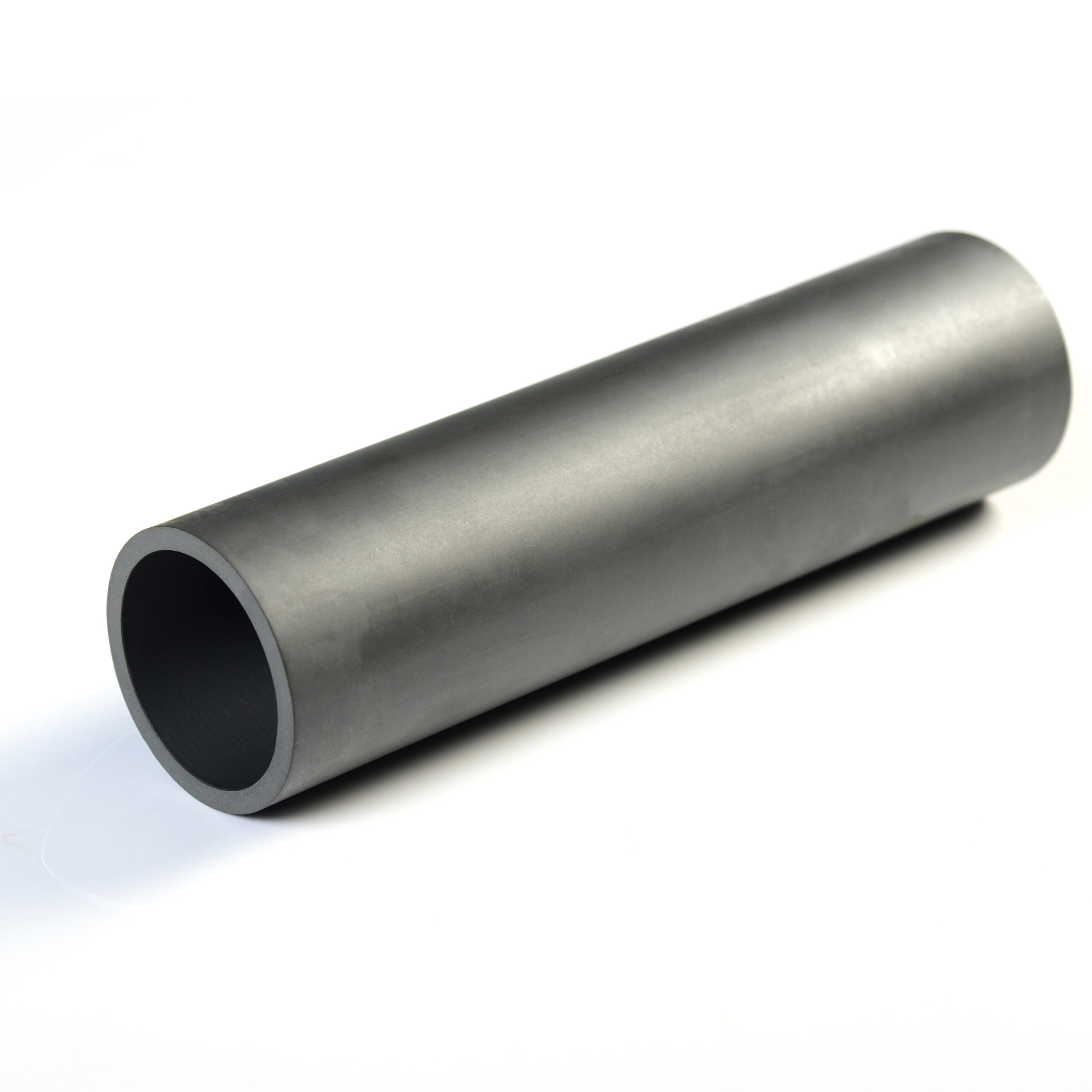

Seamless Steel Tubing for Hydraulic Lines

Product Description

Steel tubing for hydraulic lines is essential in fluid transmission systems, ensuring high-pressure fluid flow in various industrial and automotive applications. This type of tubing is designed to meet stringent standards for strength, durability, and reliability, making it ideal for hydraulic systems in machinery, construction equipment, and vehicles.

International Standards

- EN 10305– European standard for welded and seamless cold-drawn steel tubes.

- SAE J524– Automotive standard for seamless hydraulic steel tubing.

- DIN 2391– German standard for seamless steel tubes for hydraulic and pneumatic systems.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

-

-

- High Pressure Resistance: Engineered to withstand high-pressure environments, suitable for hydraulic systems.

- Corrosion Resistance: Can be phosphated or galvanized for enhanced corrosion protection, extending service life.

- Excellent Mechanical Properties: Cold drawing process ensures tight tolerances and high strength.

- Smooth Interior Surface: Ideal for smooth fluid flow, minimizing friction and wear in hydraulic lines.

- Seamless Construction: Eliminates potential weak points, providing more reliability under pressure.

- Custom Lengths: Tubes can be supplied in fixed lengths (typically 6 meters) or customized lengths to suit specific applications.

-

Main Applications

- Hydraulic Systems: Used extensively in construction machinery, mining equipment, and industrial machinery for fluid power transmission.

- Automotive Applications: Employed in automotive hydraulic lines, including power steering systems and brake systems.

- Agricultural Equipment: Found in agricultural machinery like tractors and harvesters for hydraulic control systems.

- Marine and Offshore Applications: Used in marine and offshore hydraulic systems, ensuring durability in harsh environments.

- Pneumatic Systems: Suitable for pneumatic systems that require high-quality, reliable tubing for air transmission.

Specifications

| Specification | Details |

| Material | Carbon steel, Stainless steel |

| Standards | EN 10305, SAE J524, DIN 2391 |

| Wall Thickness | 0.5mm – 10mm |

| Outer Diameter (OD) | 6mm – 100mm |

| Length | 6 meters (standard), custom lengths available |

| Finishing | Phosphated, Galvanized, Black, or as per customer requirements |

| Surface Treatment | Phosphated, Zinc coated, Passivated |

Manufacturing Process

- Raw Material: The process starts with high-quality steel billets or coils, which are selected based on the required material properties.

- Cold Drawing: Steel tubes are cold drawn to the required dimensions. This process enhances precision, surface finish, and mechanical properties like tensile strength and hardness.

- Heat Treatment: Heat treatment processes like annealing or normalizing may be applied to relieve internal stresses and ensure uniform mechanical properties.

- Surface Treatment: Steel tubing may undergo various surface treatments such as phosphating, galvanizing, or blackening to improve corrosion resistance.

- Testing: Rigorous testing procedures, including pressure testing, ultrasonic testing, and dimensional checks, are conducted to ensure quality and performance standards are met.