Hydraulic Tube Assembly Manufacturers

Product Description

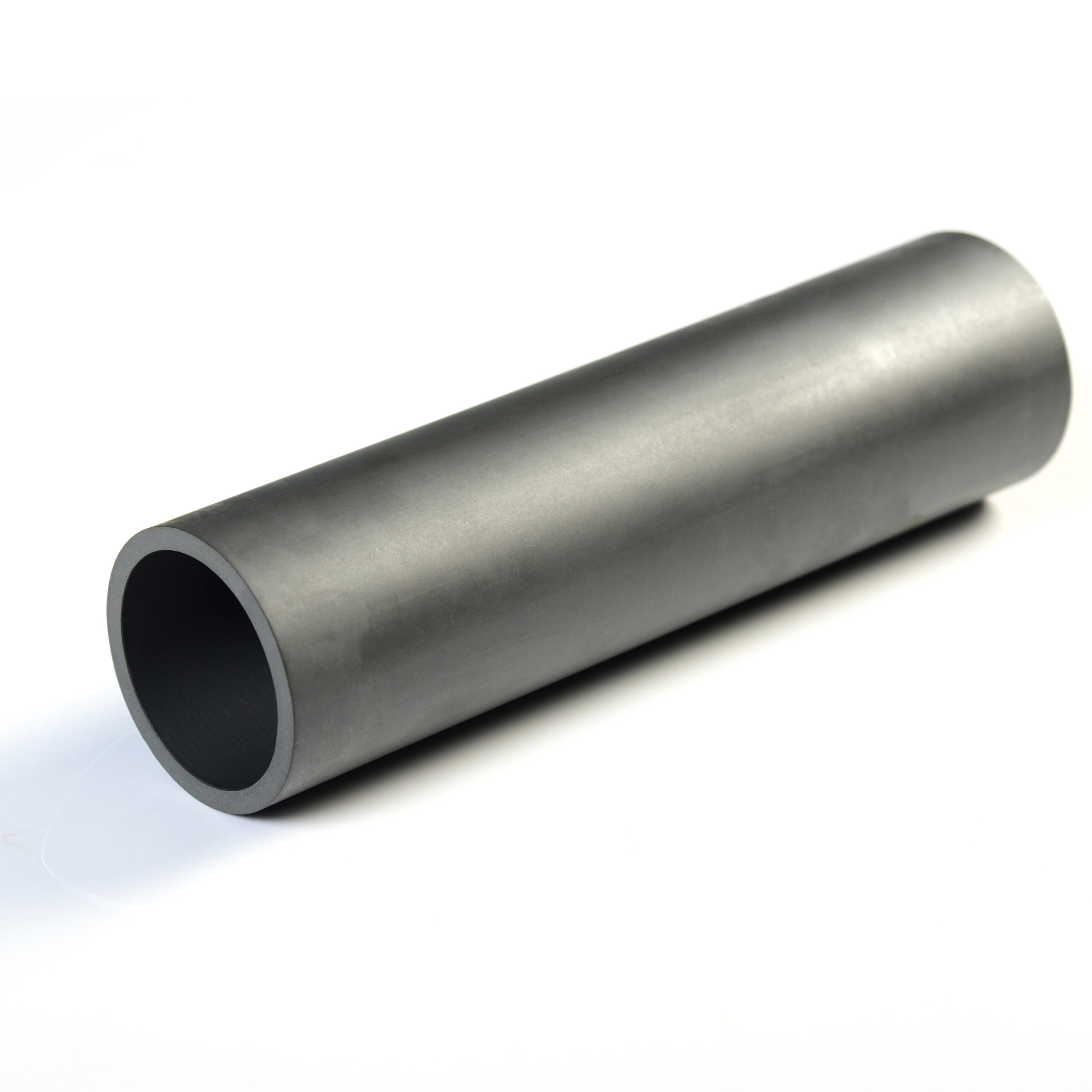

Our Hydraulic Tube Assemblies are precision-engineered solutions designed for high-performance hydraulic systems. These tubes are manufactured using top-quality materials to ensure excellent durability, reliability, and precision under pressure. Ideal for use in industries like automotive, construction, and machinery, these assemblies are built to withstand the toughest operational environments.

International Standards

- EN 10305– European standard for welded and seamless cold-drawn steel tubes.

- SAE J524– Automotive standard for seamless hydraulic steel tubing.

- DIN 2391– German standard for seamless steel tubes for hydraulic and pneumatic systems.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

-

-

- High Pressure Resistance: Designed to handle high-pressure applications without compromising safety.

- Durability: Long-lasting performance even under challenging conditions.

- Leak-proof: The design ensures reliable and secure connections, minimizing the risk of leaks.

- Precision Fit: Available in various sizes, with precision cuts and bends to meet exact requirements.

-

Main Applications

- Automotive Industry: Used in hydraulic braking systems, power steering systems, and hydraulic lifts.

- Construction Machinery: Employed in cranes, excavators, and bulldozers.

- Industrial Equipment: Vital for hydraulic presses, CNC machines, and heavy machinery.

- Oil & Gas: Utilized in drilling rigs and production facilities for fluid transportation.

Specifications

| Specification | Detail |

| Material | Carbon steel, stainless steel, or alloy steel |

| Standard | DIN 2391, EN 10305, ASTM A179, ISO 9001 |

| Surface Treatment | Galvanized, phosphated, or coated |

| Pressure Rating | High-pressure resistance, specific to application |

| Pressure Rating | High-pressure resistance, specific to application |

| Temperature Range | Suitable for temperatures between -40°C and 150°C |

Dimensions:

| Dimension | Range |

| OD (Outer Diameter) | 4mm to 100mm |

| Wall Thickness | 0.5mm to 10mm |

| Length | Customized to specification |

| Bend Radius | Customizable to fit application requirements |

Manufacturing Process

- Cold Drawing: Tubes are manufactured using cold drawing techniques to ensure high precision and smooth surface finish.

- Cutting and Bending: Tubes are precisely cut and bent to meet specific application requirements.

- Surface Treatment: Post-production treatment includes coatings like galvanizing or phosphating to protect against corrosion.

- Testing: Rigorous testing for pressure resistance and dimensional accuracy.