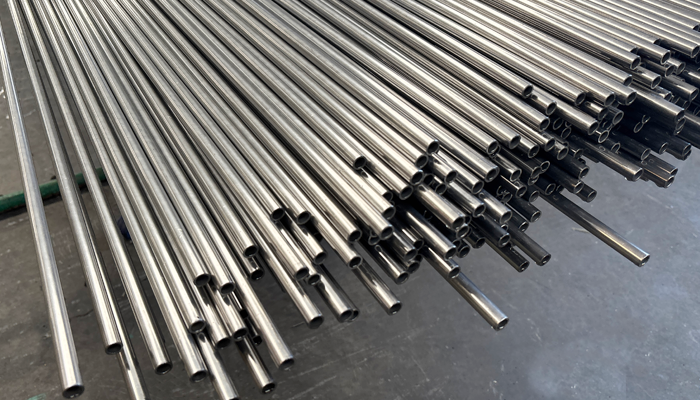

Custom Hydraulic Tubing Suppliers

Xuzhou Global Precision Steel Tube Co., Ltd. specializes in manufacturing high-quality custom hydraulic tubing tailored to meet diverse industry requirements. Our tubes are engineered for optimal performance in hydraulic and pneumatic power systems, ensuring reliability and efficiency across various applications.

Product Advantages

We utilize premium-grade materials to produce our hydraulic tubes, including:

- E235 (ST35, ST37.4)

- E355 (ST52, ST52.4)

These materials are selected for their excellent mechanical properties, ensuring durability and performance under high-pressure conditions.

Our hydraulic tubes conform to the following international standards:

- EN 10305-4 (DIN 2445/2)

- EN 10305-1 (DIN 2391)

- ASTM A179

Adherence to these standards guarantees high precision, quality, and compatibility with global industry requirements.

- High Precision:Achieved through advanced cold drawing and rolling processes, ensuring tight dimensional tolerances.

- Superior Surface Finish:Smooth internal and external surfaces reduce friction and enhance fluid flow efficiency.

- Excellent Mechanical Properties:High tensile strength and toughness suitable for high-pressure hydraulic applications.

- Corrosion Resistance:Available with various surface treatments, including galvanization and phosphating, to enhance durability.

| Parameter | Details |

| Outer Diameter (OD) | 4mm – 120mm |

| Wall Thickness (WT) | 0.5mm – 10mm |

| Length | Fixed 6 meters or customized as per request |

| Surface Treatment | Galvanized (zinc coating of 8 to 12μm), Phosphated, Bright finish |

| Delivery Condition | +N (NBK) normalized under a controlled atmosphere |

Hydraulic Tube Sizes

| OD (mm) | WT (mm) |

| 6 | 1 – 1.5 |

| 10 | 1.0 – 2.0 |

| 20 | 1.0 – 3.0 |

| 50 | 3.0 – 7.0 |

Note: Custom sizes are available upon request to meet specific application needs.

- Material Selection:High-quality raw materials are chosen to meet specific mechanical and chemical properties.

- Cold Drawing/Rolling:Tubes are formed to precise dimensions with smooth surfaces.

- Heat Treatment (NBK):Normalized under a controlled atmosphere to achieve desired mechanical properties.

- Surface Treatment:Options include galvanization, phosphating, or bright finishing for enhanced corrosion resistance.

- Quality Inspection:Rigorous testing, including eddy current testing, to ensure defect-free products.

Applications

Our custom hydraulic tubes are ideal for:

- Automotive Industry:Fuel injection systems, brake lines, and hydraulic steering systems.

- Construction Machinery:Hydraulic cylinders and fluid power systems.

- Agricultural Equipment:Hydraulic systems for tractors and harvesters.

- Industrial Equipment:Pneumatic and hydraulic control systems.

.png)