Custom Metal Hydraulic Lines for Hydraulic Equipment and Machinery

Product Description

International Standards

- DIN 2391: For seamless steel pipes for hydraulic systems and high-pressure applications.

- ASTM A179: For manufacturing hydraulic pipes suitable for high pressure and strength.

- EN 10305-4: Standard for precision tubes and hydraulic piping systems.

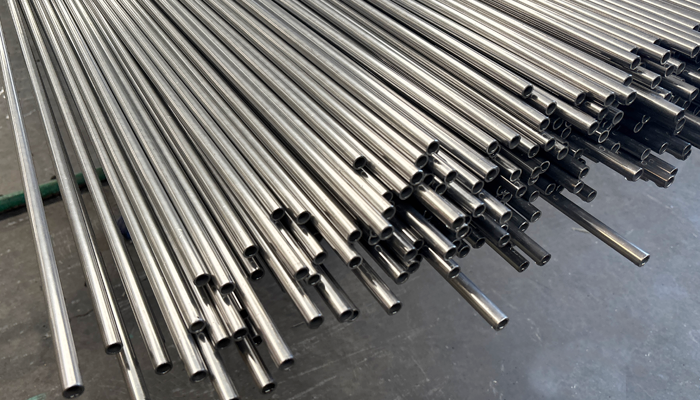

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

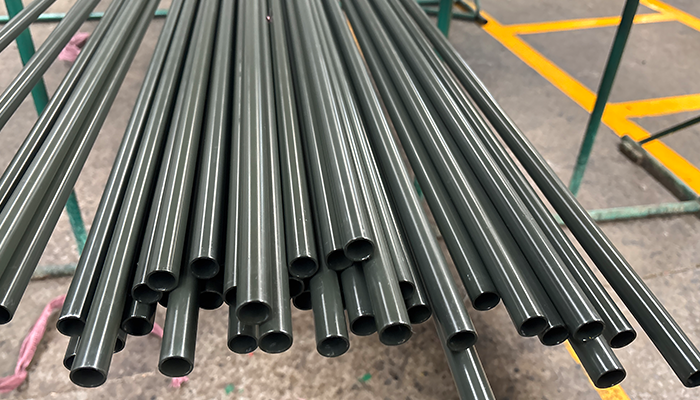

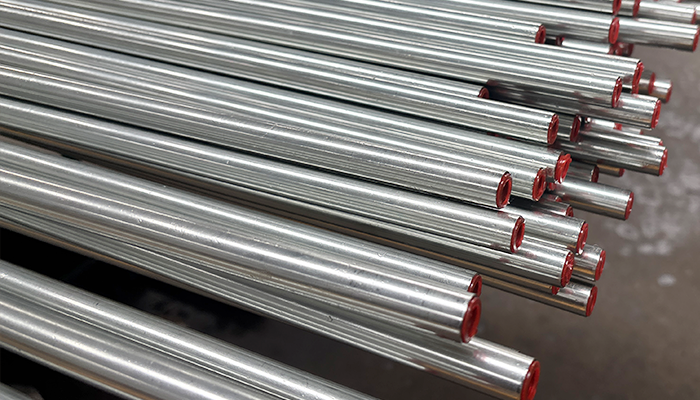

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

-

-

- High Pressure Resistance: Able to withstand extremely high hydraulic pressures, suitable for heavy machinery and hydraulic systems.

- Excellent Corrosion Resistance: Surface treatments like phosphating and galvanization enhance corrosion protection and extend service life.

- Smooth Surface: The surface finish ensures minimal friction during fluid flow, which is crucial for fluid transportation.

- Precision Dimensions: Cold drawing ensures exact measurements, ideal for precision hydraulic systems.

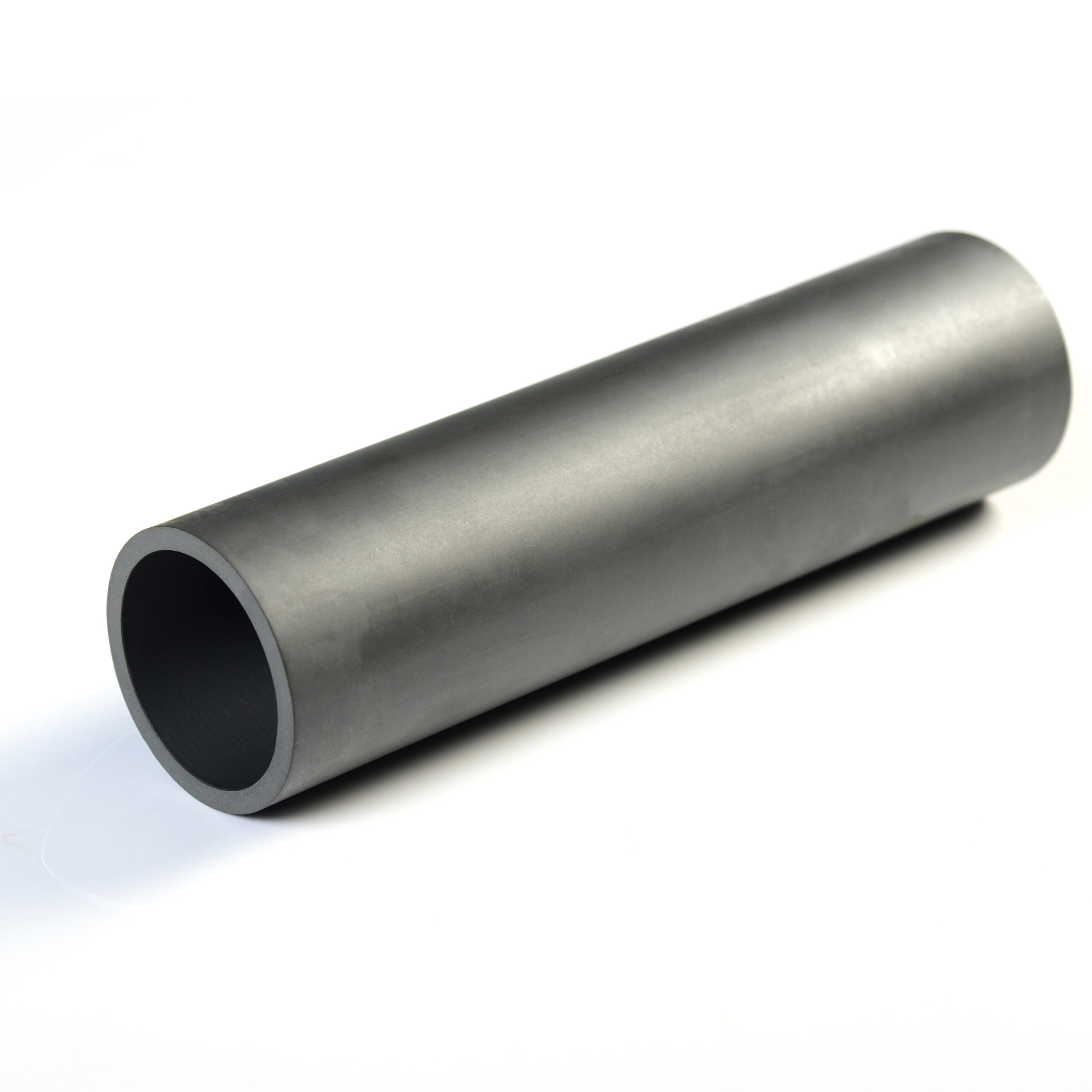

- Seamless Design: The seamless construction increases pressure resistance and enhances reliability.

-

Main Applications

- Hydraulic Equipment: Used in various hydraulic systems, including hydraulic cylinders, pumps, and valves, to transport hydraulic oil.

- Construction Machinery: Widely used in hydraulic systems of excavators, loaders, bulldozers, and other heavy machinery.

- Automotive Industry: Used in automotive hydraulic braking systems and power steering systems.

- Aerospace: Used for high-pressure fluid transfer in aerospace equipment.

- Marine Applications: Used in ship hydraulic systems and offshore oil rigs.

- Manufacturing and Metallurgical Industries: Used for high-pressure fluid transmission in machinery and equipment.

Specifications

| Specification | Details |

| Material Type | Carbon Steel, Alloy Steel, Stainless Steel |

| Diameter Range | 4mm – 100mm |

| Wall Thickness Range | 0.5mm – 20mm |

| Length | Standard 6m/pc |

| Surface Treatment | Passivation, Galvanization, Phosphating, Anti-corrosion treatments |

| Pressure Rating | Suitable for high pressure, up to 25,000 psi |

| Standards | DIN 2391, ASTM A179, EN 10305-4, etc. |

| Delivery Condition | Annealed, Normalized, Cold Drawn |

Manufacturing Process

- Cold Drawing: The cold drawing process reduces pipe diameter and increases precision, ensuring uniform thickness and strength.

- Pickling: Removal of surface oxides and impurities to enhance the surface quality of the pipe.

- Annealing: Heat treatment process to eliminate internal stress and improve material ductility and toughness.

- Phosphating/Galvanization: Enhances corrosion resistance and surface wear properties of the tubes.

- Seamless Manufacturing: Eliminates weak points from welding, ensuring higher pressure resistance and durability.

Manufacturing Methods

- Piercing: Solid steel rods are pierced to create hollow tubes.

- Cold Drawing: Tubes are drawn to the desired size with high precision, ensuring strength and durability.

- Annealing: Applied to relieve internal stress and improve mechanical properties.

- Pickling and Surface Treatment: Removal of impurities and enhancement of corrosion resistance.

- Final Testing: Pressure testing and quality checks are performed to ensure compliance with standards.