DIN 2391 Hydraulic Seamless Pipe

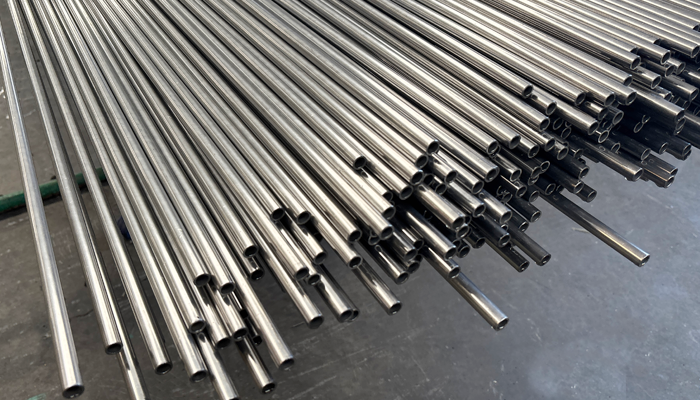

DIN 2391 Hydraulic Seamless Pipe is a high-quality steel pipe used for hydraulic applications that require high-pressure resistance. These seamless pipes are manufactured with precision, ensuring consistent performance and durability across various industries. With exceptional mechanical properties and dimensional accuracy, they are ideal for transmitting hydraulic fluids under pressure in different systems.

Product Advantages

The pipes are primarily made from carbon steel (St37, St45, etc.), which provides a perfect balance of strength, weldability, and resistance to wear. They are also available in higher grades such as alloy steel for applications requiring enhanced performance.

International Standards

These pipes comply with DIN 2391, an internationally recognized standard for seamless steel pipes used in hydraulic systems. Additionally, they meet other standards like EN 10305-4 , ensuring quality and reliability in hydraulic applications.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

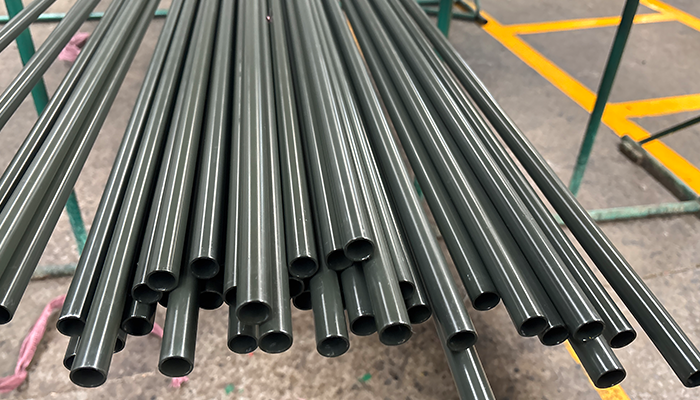

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

- High Pressure Resistance: The seamless construction ensures that the pipe can withstand high-pressure conditions without failure.

- Dimensional Accuracy: The pipes are manufactured to precise measurements, reducing material wastage and fitting errors.

- Corrosion Resistance: Designed with excellent anti-corrosion properties for a long service life, even in harsh environments.

- Seamless Design: The absence of welds means no weak points, offering greater reliability in pressure applications.

- Excellent Surface Finish: After manufacturing, the pipes are often treated to improve surface smoothness and minimize friction for fluid flow.

Surface Treatment:

-

-

- Rust Prevention: Typically, the pipes are coated with a layer of anti-corrosion oil to protect the surface during storage and transportation.

- Further Treatment Options: The surface can be processed with treatments like phosphating, pickling, or passivation to increase durability and corrosion resistance.

-

| Specification | Details |

| Material | St37, St45 |

| Standard | DIN 2391, EN 10305-4 |

| Delivery State | Cold Drawn or Normalized |

| Protective Measures | Anti-corrosion oil, plastic end caps |

Seamless Hydraulic Pipe Sizes

| Diameter (OD) | Thickness (WT) | Length |

| 6mm – 120mm | 1mm – 10mm | 6 meters (Standard) |

| Custom Sizes Available | Custom Sizes Available | Custom Lengths Available |

- Piercing: Solid steel billets are pierced to create a hollow tube.

- Acid Pickling: After piercing, the tube undergoes acid pickling to remove impurities like rust and scale from the surface.

- Phosphating: A phosphate coating is applied to improve corrosion resistance and provide better lubrication for the drawing process.

- Cold Drawing: The tube is drawn through a die to reduce its diameter and wall thickness, enhancing precision and strength.

- Annealing: A heat treatment process to relieve internal stresses, ensuring better mechanical properties.

Applications

- Hydraulic Systems: Used in various hydraulic systems for fluid transfer, including construction machinery, industrial presses, and hydraulic pumps.

- Automotive: Applied in car braking systems, fuel lines, and other hydraulic components.

- Engineering Equipment: Used in excavators, loaders, cranes, and other heavy machinery for fluid transmission.

- Oil and Gas: Employed in high-pressure piping systems for offshore and onshore oil rigs.

- Aerospace: Hydraulic pipes are also utilized in aircraft systems requiring high-pressure fluid transfer.