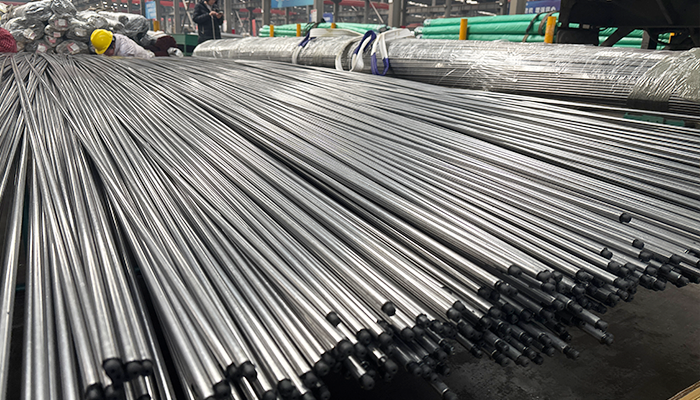

DIN 2391 ST35 Seamless Pipe for Hydraulic Systems

The DIN 2391 ST35 Seamless Pipe for Hydraulic Systems is a high-quality, precision-engineered pipe designed specifically for use in hydraulic applications. It is manufactured from ST35 carbon steel, which offers superior strength, durability, and excellent mechanical properties. This seamless pipe ensures leak-free performance and can withstand high pressures, making it ideal for hydraulic systems that require reliability and precision.

Product Advantages

The pipe is made from ST35 carbon steel, a common material used for manufacturing seamless pipes. ST35 is a low-carbon steel that is known for its good weldability, formability, and high tensile strength. It has low carbon content, which enhances its ability to be easily welded and shaped while maintaining high structural integrity under pressure.

International Standards:

- DIN 2391: A German standard specifying the technical delivery conditions for seamless steel pipes used in hydraulic systems.

- EN 10305-4: An international standard for seamless steel tubes, specifically for use in hydraulic and pneumatic systems.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

- High Strength: ST35 steel offers excellent tensile strength and resistance to internal and external pressures, ensuring the pipe performs reliably under high-pressure conditions.

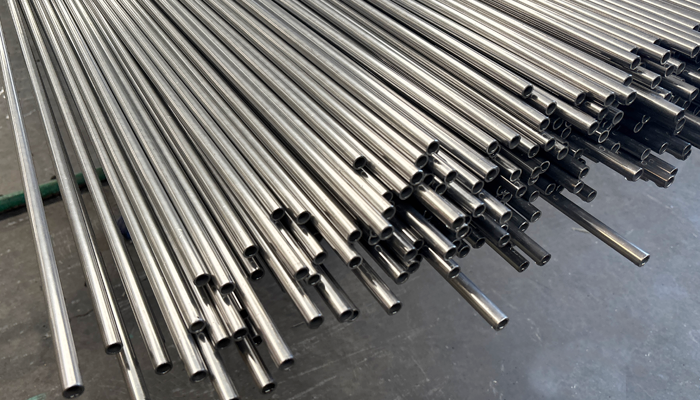

- Seamless Construction: The pipe’s seamless design eliminates potential weak points from welding, making it stronger and more reliable for use in critical hydraulic systems.

- Precision: Manufactured with high precision, this seamless pipe provides consistent dimensions and smooth inner surfaces, which are essential for efficient fluid flow in hydraulic systems.

- Durability: Resistant to corrosion and wear, the ST35 steel ensures the pipe’s longevity in various environments.

Surface Treatment:

-

-

- Smooth Surface: The pipe has a smooth inner and outer surface, which minimizes friction and flow resistance when used in hydraulic systems.

- Protection: The surface can be treated with anti-corrosion oils to prevent rust during storage and transportation. Further coatings or surface treatments, such as phosphating, can be applied depending on customer requirements.

-

| Specification | Details |

| Material | ST35 Carbon Steel |

| Standard | DIN 2391, EN 10305-4 |

| Heat Treatment | Normalized (+N) |

| Protection | Anti-corrosion oil, plastic end caps |

| Manufacturing Process | Cold Drawn, Seamless |

Dimensions:

| Dimensions | Range |

| Outer Diameter (OD) | 4 mm to 120 mm |

| Wall Thickness (WT) | 0.5 mm to 10 mm |

| Length | Standard: 6 meters, custom lengths available |

Dimensions:

| Dimension Range | Details |

| Outer Diameter (OD) | 4 mm to 120 mm |

| Wall Thickness (WT) | 0.5 mm to 10 mm |

| Length | Standard 6 meters or customized lengths |

- Piercing: Solid steel billets are initially pierced to form hollow tubes.

- Acid Pickling: The pipes are acid pickled to remove scale, rust, and impurities from the surface, ensuring a clean and smooth finish.

- Cold Drawing: The tube undergoes a cold drawing process to reduce its diameter and wall thickness while improving mechanical properties such as strength and hardness.

- Heat Treatment: The pipe is normalized to relieve stresses induced during the drawing process, ensuring better mechanical performance.

- Surface Treatment: Anti-corrosion oils are applied to the surface to prevent rust during handling and transport. Additional coatings like phosphating may be applied as per the requirements.

Applications

- Hydraulic Systems: Ideal for hydraulic piping systems in industries requiring high-pressure performance, including automotive, construction, and manufacturing.

- Industrial Equipment: Used in various industrial machinery and equipment, including hydraulic presses, pumps, and valves.

- Automotive Industry: Employed in automotive hydraulic systems such as power steering and brake lines.

- Agricultural Equipment: Used in agricultural machinery to ensure reliable fluid transfer in hydraulic systems.

- Construction Equipment: Suitable for heavy-duty construction machinery, including excavators, bulldozers, and cranes.