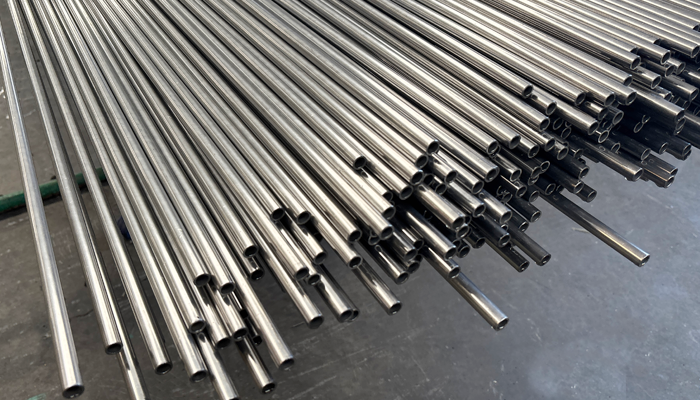

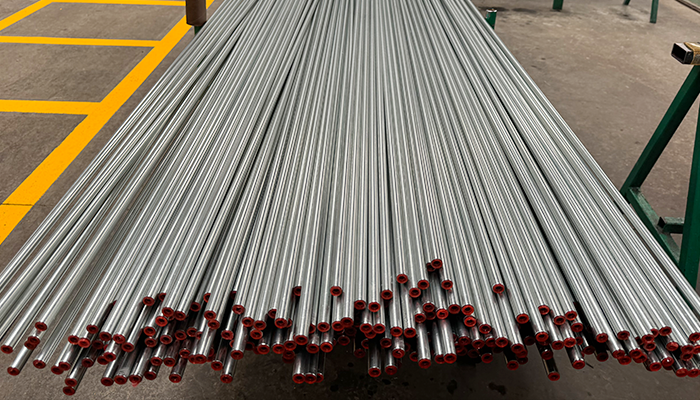

DIN 2391 St37.4 Cold Drawn Seamless Tubing

DIN 2391 St37.4 cold drawn seamless tubing is a high-quality precision tube designed for a variety of industrial and hydraulic applications. Known for its outstanding mechanical properties and dimensional accuracy, this seamless steel tube is ideal for use in demanding environments where high performance and reliability are essential.

Product Advantages

The tubing is manufactured from St37.4 carbon steel, which offers excellent ductility, weldability, and strength. This steel grade is ideal for producing tubes that can withstand high pressures and external stresses. The material composition includes carbon, manganese, phosphorus, and sulfur, which enhance its overall mechanical properties.

International Standards:

- DIN 2391 St37.4: This standard specifies seamless cold drawn steel tubes for precision applications. It guarantees that the tubes meet rigorous quality control and performance standards.

- EN 10305-1: This European standard applies to seamless tubes made from carbon and alloy steels used for hydraulic and mechanical applications.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

- Precision and Accuracy: Cold drawing ensures tight tolerances and high dimensional accuracy, making the tubes suitable for applications requiring precision.

- High Strength: The St37.4 material ensures high tensile strength, making the tubes capable of withstanding high internal and external pressures.

- Seamless Design: The seamless construction provides better structural integrity and resistance to leaks, compared to welded tubes.

- Smooth Surface: Cold drawing results in a smooth exterior and interior surface, reducing friction and improving fluid flow in hydraulic systems.

Surface Treatment:

-

-

- The tubing is typically treated with rust-proof oil to protect against corrosion during storage and transportation.

- It can also undergo surface treatments such as phosphating or pickling to improve corrosion resistance and ensure smooth finishes.

-

| Specification | Details |

| Material | St37.4 Carbon Steel |

| Standard | DIN 2391, EN 10305-1 |

| Delivery State | +N (Normalized in controlled atmosphere) |

| Protective Coating | Rust-proof oil, plastic end caps |

Dimensions:

| Size Range | Details |

| Outer Diameter (OD) | 4 mm to 120 mm |

| Wall Thickness (WT) | 0.5 mm to 10 mm |

| Length | Standard 6 meters or customized lengths |

- Piercing: Solid steel billets are first pierced to create a hollow tube shape.

- Acid Pickling: The tube is treated with acid to remove impurities and rust from the surface.

- Phosphating: A coating is applied to enhance the corrosion resistance of the steel.

- Cold Drawing: The tube is drawn through dies to reduce its diameter and wall thickness while improving its mechanical properties.

- Annealing: The tube is heat-treated to relieve internal stresses.

Applications

- Automotive Industry: Ideal for use in hydraulic systems such as brake lines and fuel injection systems due to its precision and strength.

- Construction Machinery: Widely used in hydraulic cylinders and tubing systems for excavators, loaders, and bulldozers.

- General Hydraulic Systems: These tubes are essential in fluid transfer and pressure control applications, providing reliable and leak-free performance.

- Pressure Systems: The seamless, high-strength nature of the tube makes it suitable for high-pressure fluid and gas transmission systems.