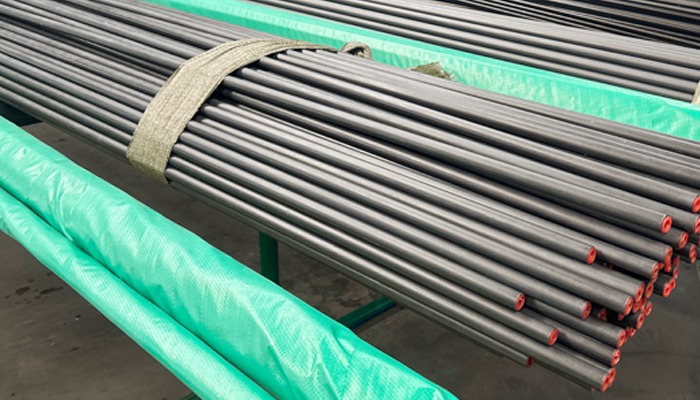

DIN 2391 ST37.4+NBK High Pressure Hydraulic Piping

Product Description

DIN 2391 ST37.4+NBK High Pressure Hydraulic Piping is a high-quality seamless steel pipe designed for use in hydraulic systems, particularly those requiring high pressure resistance. Manufactured according to the DIN 2391 standard, these pipes offer exceptional strength, reliability, and durability in demanding environments. The ST37.4+NBK steel grade ensures excellent mechanical properties, including high tensile strength and impact resistance, making it ideal for high-pressure applications in industries such as automotive, manufacturing, and construction.

Product Advantages

Material

- Steel Grade:

- ST37.4+NBK

- Material Properties:

- Excellent tensile strength and toughness, able to withstand high-pressure conditions.

- Good weldability and formability for easy fabrication.

- Enhanced surface finish and uniformity due to the NBK(normalized, bright) treatment.

International Standards

- DIN 2391: Precision steel tubes for hydraulic and pneumatic systems.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

- High Pressure Resistance: Designed to handle extreme pressure conditions in hydraulic systems, ensuring smooth operation and preventing leakage.

- Corrosion Resistance: Offers excellent protection against corrosion, particularly in harsh environments.

- Bright Surface Finish: The NBK(normalized, bright) finish provides smooth, clean, and uniform surfaces, ensuring reliable fluid transfer and reducing wear.

- Precision Manufacturing: Manufactured using cold drawing processes, ensuring tight tolerances and precise dimensions for efficient hydraulic performance.

- Durability: Provides long-lasting performance and reliability in high-pressure applications.

Specifications

| Parameter | Details |

| Standard | DIN 2391 |

| Steel Grade | ST37.4+NBK |

| Surface Finish | Normalized, Bright (NBK) |

| Applications | Hydraulic and Pneumatic Systems |

Dimensional Specifications

| Outer Diameter (mm) | Wall Thickness (mm) | Length (m) |

| 6 – 80 | 1.0 – 10.0 | 6.0 (Customizable) |

Production Process

- Cold Drawing: Ensures precise dimensions and smooth surfaces, essential for high-pressure fluid flow.

- Normalizing (NBK Treatment): The tube is normalized to improve internal structure, ensuring enhanced mechanical properties and surface finish.

- Surface Finishing: Bright, smooth finish reduces friction, increasing the pipe’s efficiency in high-pressure systems.

- Quality Control: Comprehensive testing and inspection, including pressure testing, dimensional checks, and non-destructive testing (NDT), to meet high-quality standards.

Applications

- Hydraulic Systems: Essential for transporting high-pressure fluids in hydraulic systems such as pumps, valves, and actuators.

- Automotive Industry: Used in the construction of hydraulic brake systems, steering systems, and powertrains.

- Construction Machinery: Employed in hydraulic systems of construction machinery such as excavators, cranes, and bulldozers.

- Industrial Equipment: Ideal for various industrial machinery requiring high-pressure fluid systems.

- Oil & Gas: Applied in the transmission of high-pressure fluids in oil and gas fields.

- Agriculture: Suitable for hydraulic systems in agricultural machinery like tractors and harvesters.

Why Choose DIN 2391 ST37.4+NBK High Pressure Hydraulic Piping?

- Compliance with International Standards: Manufactured according to DIN 2391, ensuring reliability and high performance in hydraulic systems.

- Superior Mechanical Properties: High tensile strength and durability make it perfect for high-pressure environments.

- Precision and Consistency: Cold-drawn and NBK-treated for precise dimensions, smooth surfaces, and uniformity.

- Long-Term Reliability: Built to withstand harsh conditions and high-pressure systems for extended service life.