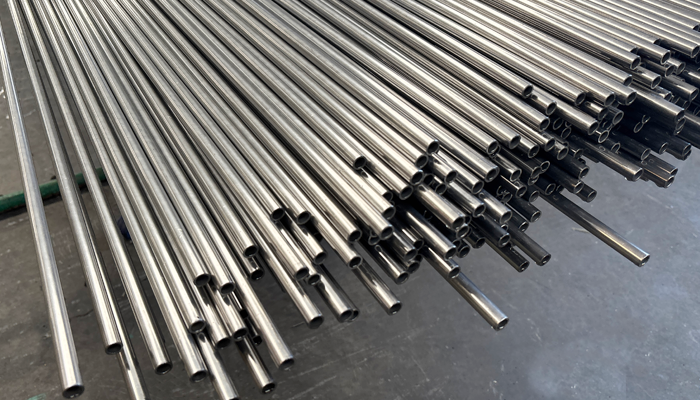

DIN 2391C Seamless Hydraulic Tube

Product Description

The DIN 2391C Seamless Hydraulic Tube is a high-performance hydraulic tube made from precision seamless steel. Designed to withstand high pressures and offer excellent durability, this tube is perfect for hydraulic systems that require consistent and reliable fluid transmission. Manufactured according to the DIN 2391C standard, it ensures high strength, corrosion resistance, and superior surface finish for a wide range of industrial applications.

Product Advantages

Materials

- Steel Grade: Typically made from St 35, a low-carbon steel that offers excellent tensile strength and ductility.

Properties:

- Good resistance to wear and tear, ensuring long-lasting performance.

- High mechanical properties, making it ideal for high-pressure hydraulic applications.

International Standards

- DIN 2391C: This standard specifies seamless tubes for hydraulic and pneumatic systems that are cold drawn and offer precision.

- EN 10305-1: European standard for seamless steel tubes used in hydraulic and mechanical applications.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

-

- Seamless Construction: Provides superior strength and uniformity compared to welded alternatives.

- High Precision: Manufactured to strict tolerances, offering excellent dimensional accuracy for fluid systems.

- Corrosion Resistance: Excellent resistance to corrosion and environmental factors, ideal for outdoor or harsh environments.

- Durability: Built to withstand high pressure, ensuring safe and reliable fluid transmission in hydraulic systems.

- Smooth Surface Finish: Ensures reduced friction and enhances the longevity of hydraulic systems.

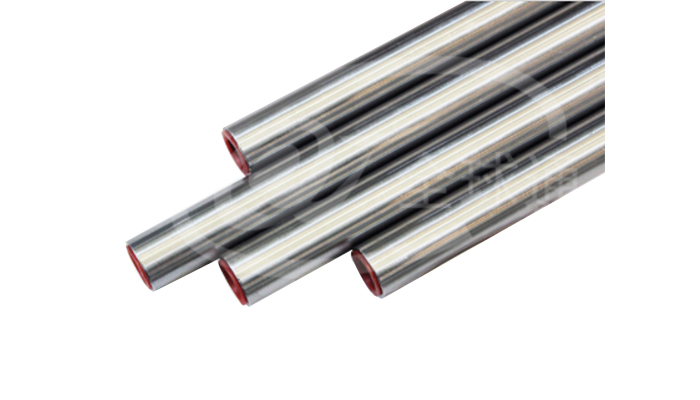

Surface Finish

-

-

- Bright Annealed Surface: The tube undergoes a bright annealing process that provides a smooth, polished surface finish, reducing the risk of corrosion and increasing fluid flow efficiency.

-

Specifications

| Specification | Details |

| Standard | DIN 2391C |

| Steel Grade | St 35 |

| Application | Hydraulic systems, pneumatic applications |

Hydraulic Seamless Tube Sizes

| Outside Diameter (mm) | Wall Thickness (mm) | Length (m) |

| 6 – 100 | 1.0 – 10.0 | 6.0 (customizable) |

Manufacturing Process

- Cold Drawing: The tube is cold drawn to achieve precise dimensions and enhanced mechanical properties.

- Bright Annealing: After cold drawing, the tube undergoes a bright annealing process that improves its surface finish and provides additional corrosion resistance.

- Surface Treatment: Additional surface treatments may be applied to enhance corrosion resistance and durability.

- Quality Control: The tubes undergo rigorous quality checks, including dimensional inspection, pressure testing, and non-destructive testing (NDT), to ensure they meet the highest standards.

Applications

- Hydraulic Systems: Ideal for fluid transmission in high-pressure systems such as hydraulic cylinders, pumps, and valves.

- Pneumatic Applications: Used in pneumatic systems for efficient fluid control.

- Automotive Industry: Applied in automotive hydraulic systems, including brake lines and steering systems.

- Industrial Machinery: Used in various industrial machinery and equipment, including manufacturing and injection molding systems.

Why Choose DIN 2391 ST 35 NBK Cold Drawn Seamless Steel Tube?

- Precision: Cold drawing and bright annealing processes ensure high precision and excellent surface quality, making this tube ideal for hydraulic systems.

- Strength & Durability: With its seamless construction and high resistance to pressure and corrosion, it provides long-lasting reliability in harsh operating conditions.

- Wide Applications: Perfect for hydraulic, pneumatic, automotive, and industrial machinery, offering versatility across different industries.