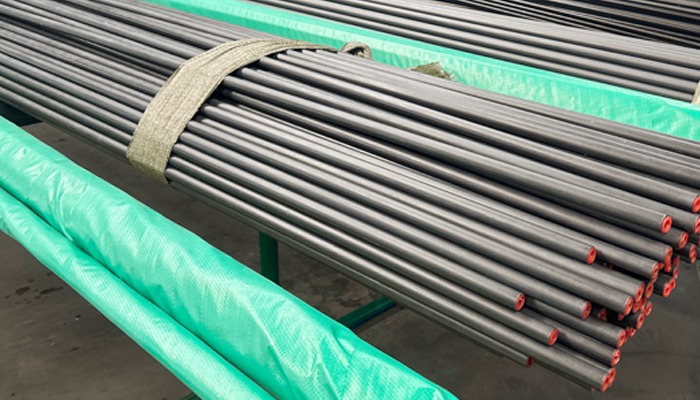

Din 2391/C St37.4 Cold Drawn Seamless Carbon Steel Pipe

The Din 2391/C St37.4 Cold Drawn Seamless Carbon Steel Pipe is a high-quality, precision-made pipe designed for various industrial applications. Known for its excellent mechanical properties and dimensional accuracy, it’s a reliable choice for high-pressure systems.

Product Advantages

Made from St37.4 carbon steel, this material offers good ductility, weldability, and strength, ideal for handling internal and external pressures. It also ensures easy processing and high-quality performance.

International Standards

Complies with DIN 2391/C, EN 10305-4 and EN 10305-1, , meeting international quality standards for seamless steel pipes used in hydraulic systems and high-pressure applications.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

-

-

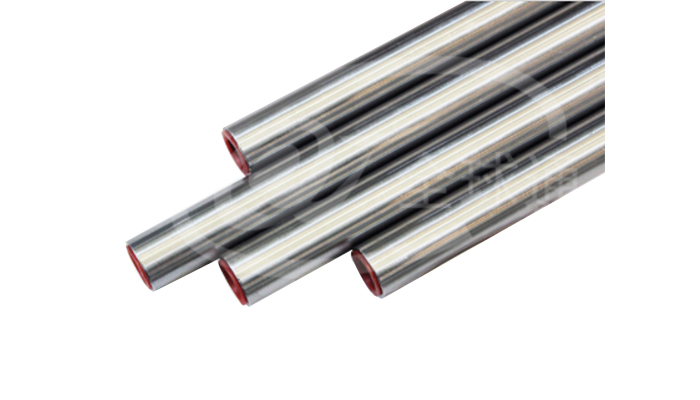

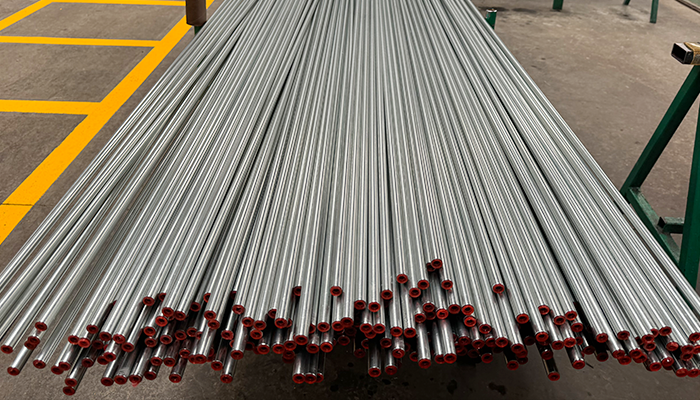

- High Precision: Cold drawn to ensure consistent outer diameter and wall thickness, making it easy to integrate into complex systems.

- Strong: Built to withstand high pressures, thanks to St37.4 carbon steel.

- Smooth Surface: Minimizes friction for fluid flow and enhances corrosion resistance with optional treatments.

- Seamless: Ensures no weak points, reducing the risk of leaks and increasing reliability.

-

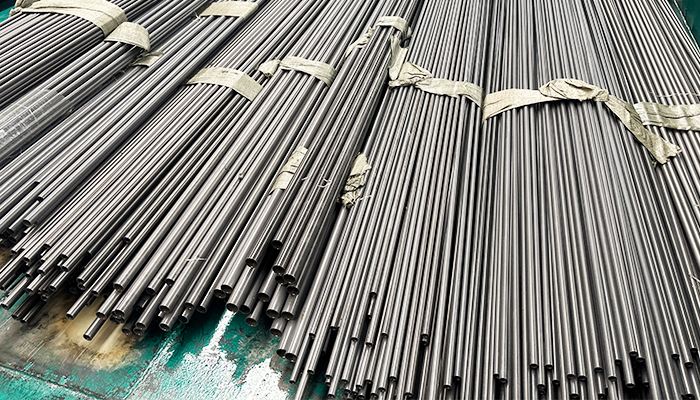

Surface

-

-

- The pipe is coated with anti-rust oil to prevent corrosion during storage and transport. Optional surface treatments like pickling, phosphating, or passivation can be applied for better corrosion resistance.

-

| Specification | Details |

| Steel Grade | St37.4 |

| Standards | DIN 2391/C, EN 10305-4, EN 10305-1 |

| Delivery State | +N (Normalized) |

| Protection | Anti-rust oil coating, plastic end caps |

Dimensions

| Dimension | Range |

| Outer Diameter (OD) | 4 – 120 mm |

| Wall Thickness (WT) | 0.5 – 10 mm |

| Length | 6 meters (custom lengths available) |

- Piercing: Steel billets are pierced to form hollow tubes.

- Pickling: Removes rust and impurities.

- Phosphating: Enhances corrosion resistance.

- Cold Drawing: Reduces pipe size and improves strength and precision.

- Annealing: Relieves internal stress and maintains pipe integrity.

Applications

- Automotive: Used in brake lines, fuel injection systems, and other hydraulic components.

- Construction Machinery: In hydraulic cylinders and piping for heavy-duty machines.

- Railway: For braking systems and suspension components.

- Shipbuilding: Hydraulic systems on ships, providing strength and corrosion resistance.

- General Hydraulic Systems: Reliable for fluid transport in various industries.