EN 10305-1 Hydraulic Steel Tube

Product Description

EN 10305-1 Hydraulic Steel Tube is a precision cold-drawn seamless steel tube primarily used for high-pressure fluid transmission in hydraulic systems. Manufactured to the EN 10305-1 standard, this steel tube is ideal for a range of industrial applications, offering excellent mechanical properties and dimensional accuracy. It is specifically designed to withstand high-pressure conditions and maintain a stable flow of hydraulic fluid in demanding environments.

Product Advantages

Material

- Steel Grades:

- E235+N, E355+N

- Material Properties:

- High tensile strength for reliable performance under pressure.

- Excellent ductility to prevent cracks and enhance system durability.

- Resistance to corrosion when treated with protective surface coatings.

International Standards

-

- EN 10305-1: Precision seamless steel tubes for hydraulic and pneumatic power systems.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

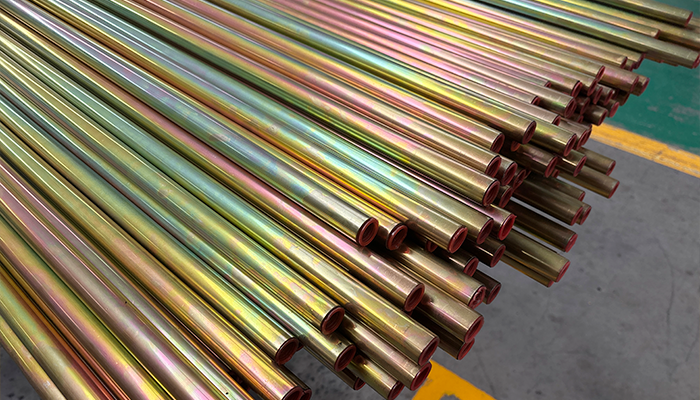

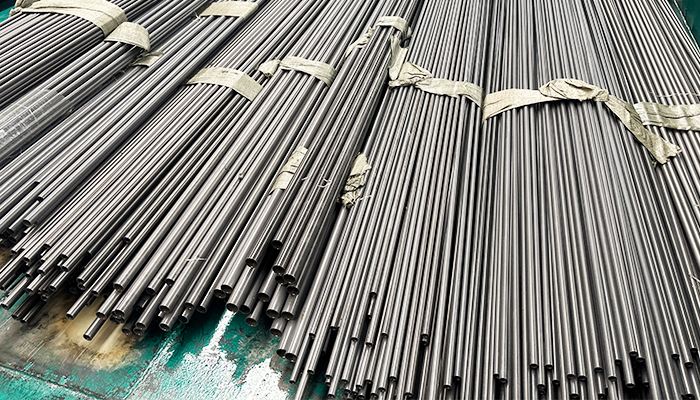

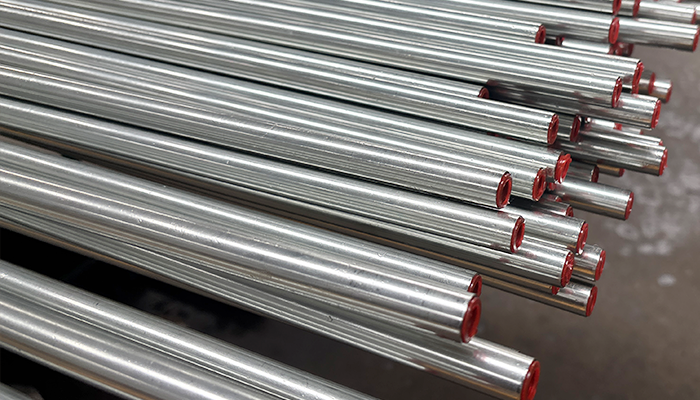

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

- High Pressure Resistance: Suitable for high-pressure hydraulic applications such as fluid transmission in cylinders, pumps, and valves.

- Dimensional Accuracy: Cold-drawn process ensures tight tolerances and smooth surfaces for seamless integration.

- Corrosion Resistance: Available with surface treatments like zinc plating, black oxide, and phosphating for enhanced protection against environmental factors.

- Efficient Fluid Flow: Smooth inner surfaces reduce friction, minimizing pressure drops and wear on hydraulic components.

- Customization: Available in a range of sizes, lengths, and finishes to meet specific application requirements.

Specifications

| Parameters | Details |

| Steel Grades | E235+N, E355+N |

| Surface Treatment | Zinc-Plated, Phosphated |

| Applications | Hydraulic and pneumatic systems |

Dimensional Specifications

| Outer Diameter (mm) | Wall Thickness (mm) | Standard Length (m) |

| 6 – 120 | 1.0 – 10.0 | 6.0 (Customizable) |

Production Process

- Cold Drawing: Ensures precision and smooth surface for optimal fluid transmission.

- Heat Treatment: Normalizing or annealing to enhance mechanical properties and material uniformity.

- Surface Treatments: Zinc plating, phosphating, to prevent corrosion and improve lifespan.

- Quality Control: Full inspection, including pressure testing, dimensional checks, and non-destructive testing (NDT), to meet international standards.

Applications

- Hydraulic Systems: Essential for use in high-pressure hydraulic applications such as cylinders, pumps, and control systems.

- Pneumatic Systems: Suitable for air pressure systems used in industrial automation and mechanical processes.

- Automotive: Applied in brake lines, power steering systems, and other automotive hydraulic components.

- Construction Equipment: Used in hydraulic systems of machinery like excavators, loaders, and cranes.

- Agricultural Machinery: Reliable for fluid transmission in agricultural equipment such as tractors and harvesters.

- Oil & Gas Industry: Perfect for demanding applications requiring high-pressure fluid transmission.

Why Choose EN 10305-1 Hydraulic Steel Tube?

- Compliant with international standards for performance and quality.

- Offers superior pressure resistance and corrosion protection for long-lasting reliability.

- High-precision manufacturing ensures consistent quality and ease of installation.

- Customizable sizes and surface finishes to suit various applications and environments.