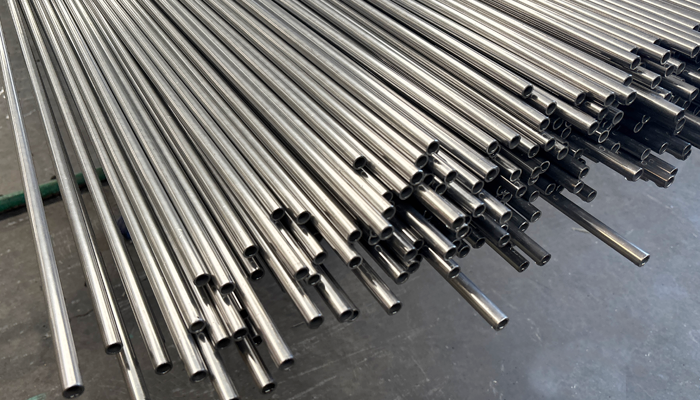

EN 10305-4 E235 Zinc Plated Hydraulic Tubing

EN 10305-4 E235 Zinc Plated Hydraulic Tubing is a high-quality, corrosion-resistant steel tube designed specifically for hydraulic applications. Manufactured to strict standards, this tubing is suitable for use in hydraulic systems requiring high pressure and durability. The zinc-plated surface provides added protection against corrosion, ensuring the longevity and reliability of hydraulic systems in harsh environments.

Product Advantages

The tubing is made from E235 steel, a high-quality carbon steel that offers excellent strength, formability, and weldability. The material is carefully selected for its resistance to wear and fatigue, making it ideal for high-pressure hydraulic systems.

International Standards:

- EN 10305-4: European standard for seamless steel tubes used in hydraulic and pneumatic systems.

- E235: A grade of carbon steel used for seamless hydraulic tubing, which ensures uniformity in mechanical properties, such as yield strength and tensile strength.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

- Corrosion Resistance: Zinc plating provides excellent corrosion protection, especially in environments prone to rust and moisture, extending the service life of hydraulic systems.

- High Strength: Made from E235 carbon steel, the tubing offers good tensile strength, making it suitable for high-pressure applications.

- Seamless Design: The seamless construction eliminates potential weak points found in welded tubes, offering superior strength and reliability under pressure.

- Precision Manufacturing: High dimensional accuracy ensures the tubes are suitable for precise hydraulic systems with minimal leakage risk.

Surface Treatment:

- Zinc Plated: The tubing features a zinc-plated coating that helps prevent corrosion and enhances the tube’s resistance to environmental elements, ensuring longer life and better performance in wet and harsh conditions.

- Smooth Finish: The tubes are produced with a smooth internal and external finish, reducing friction for fluids and improving system efficiency.

| Specification | Details |

| Material | E235 carbon steel |

| Standard | EN 10305-4, E235 |

| Coating | Zinc-plated |

| State | +N (Normalized condition) |

| Protection | Zinc coating, end caps (standard) |

Dimensions:

| Dimension Range | Details |

| Outer Diameter (OD) | 6 mm to 160 mm |

| Wall Thickness (WT) | 0.5 mm to 12 mm |

| Length | Standard 6 meters, custom lengths available |

- Piercing: The process starts with a solid steel billet, which is pierced to form a hollow tube.

- Pickling: After piercing, the tube is pickled to remove impurities and oxidation from the surface.

- Zinc Plating: The tubes are then coated with zinc to provide corrosion resistance.

- Cold Drawing: The tube undergoes a cold drawing process to achieve the desired diameter and wall thickness, while enhancing mechanical properties such as strength and hardness.

- Annealing: The tubes are annealed to relieve any internal stresses created during the drawing process.

- Finishing: A smooth finish is applied to the internal and external surfaces to improve flow efficiency and reduce friction.

Applications

-

- Hydraulic Systems: Ideal for use in hydraulic piping systems that require high strength and resistance to corrosion, such as those found in construction, agriculture, and industrial machinery.

- Automotive Industry: Suitable for automotive hydraulic systems, including steering and braking systems.

- Pressure Lines: Commonly used in pressure lines and other applications where the tubing must withstand high pressures and exposure to moisture.

- Marine and Offshore: The zinc plating makes this tubing especially suitable for marine environments, offering additional protection against the effects of saltwater and humidity.