EN 10305-4 E235+N Equivalent Metric Hydraulic Tube

Product Description

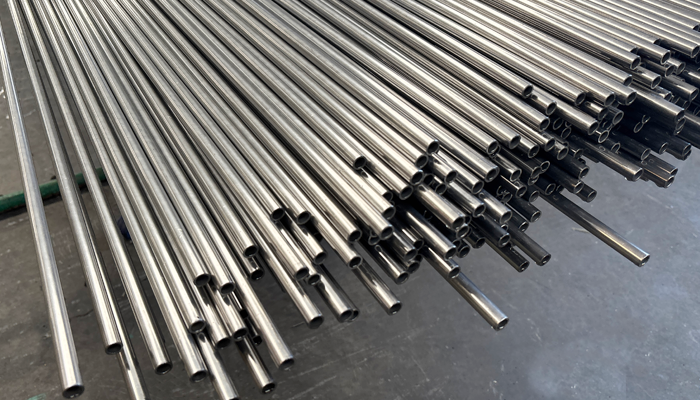

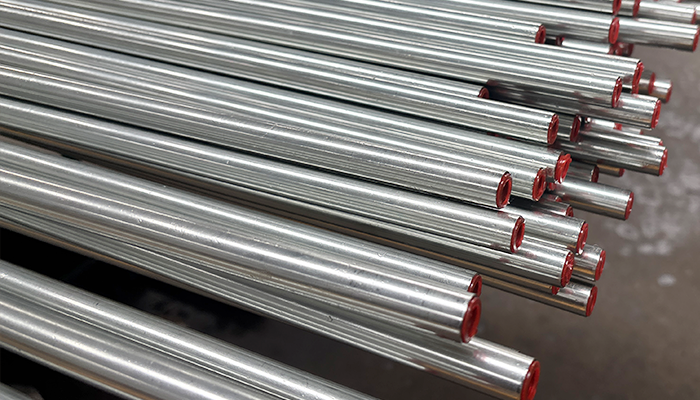

The EN 10305-4 E235+N Metric Hydraulic Tube is a high-precision cold-drawn seamless steel tube specifically designed for hydraulic systems. It meets the EN 10305-4 standard, ensuring high dimensional accuracy, excellent surface finish, and outstanding mechanical properties. The E235+N grade signifies normalized steel with enhanced performance under pressure, making it a reliable choice for hydraulic and pneumatic applications.

Product Advantages

Materials

- Steel Grade:

- E 235+N

- Material Properties:

- High tensile strength to withstand the high-pressure conditions typical in hydraulic systems.

- Excellent weldability and formability, allowing for ease of fabrication.

- Enhanced corrosion resistance when surface-treated.

International Standards

-

- EN 10305-4: Cold-drawn precision steel tubes for hydraulic and pneumatic applications.

Dimension

| OD | Thickness(m m) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

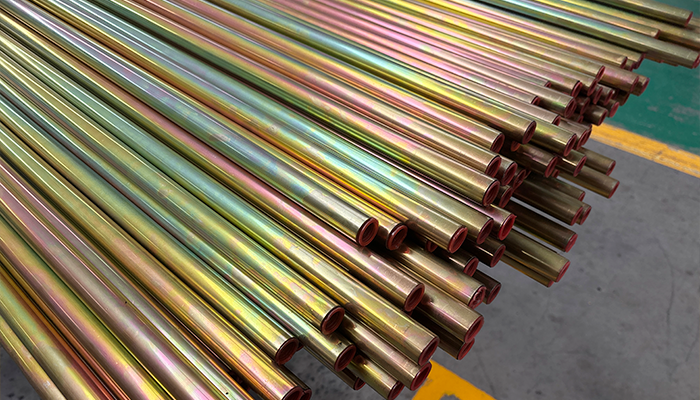

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

- Superior Dimensional Precision: Guarantees consistent flow efficiency and easy installation.

- High Pressure Resistance: Designed to withstand high-pressure hydraulic systems without deformation.

- Corrosion Resistance: Can be treated with surface finishes like galvanization or phosphating for long-term durability.

- Excellent Mechanical Properties: Ensures optimal strength and toughness under challenging conditions.

- International Standard Compliance: Manufactured to meet EN 10305-4 requirements.

Production Process

The tube is manufactured through a cold-drawing process and is then normalized to ensure uniform material properties. Surface treatments such as galvanizing, phosphating, or black oxidation can be applied to enhance corrosion resistance and meet specific application needs.

Applications

- Hydraulic Systems: Ideal for hydraulic cylinders, lines, and components in industrial and mobile applications.

- Pneumatic Systems: Used in compressed air systems where high strength and precision are required.

- Automotive: Suitable for power steering, braking systems, and suspension components.

- Industrial Equipment: Widely used in machinery requiring precise fluid transfer and pressure containment.

- Oil and Gas: Excellent for high-pressure fluid transfer in offshore and onshore environments.

International Standards Compliance

- EN 10305-4 (Seamless steel tubes for hydraulic and pneumatic power systems)

- DIN 2391 (Precision steel tubes)

Why Choose EN 10305-4 E235+N Metric Hydraulic Tube?

- High precision for seamless integration into hydraulic systems

- Reliable performance under extreme pressure and environmental conditions

- Customizable sizes to fit specific system requirements

- Internationally recognized quality standards for guaranteed reliability