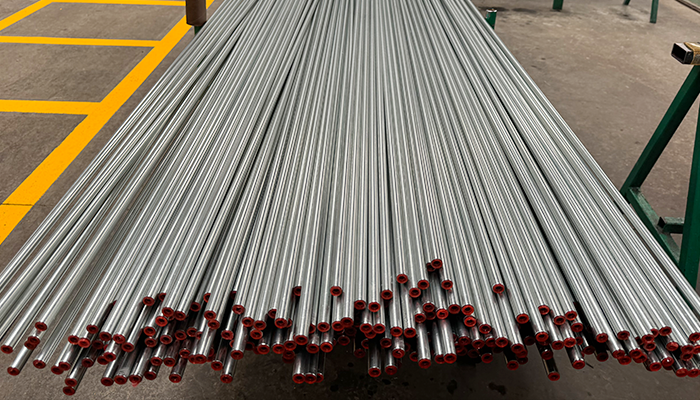

EN 10305-4 E235+N High Pressure Steel Pipe

Product Description

The EN 10305-4 E235+N High Pressure Steel Pipe is designed for use in hydraulic and pneumatic systems where high pressure resistance is required. Manufactured from E235+N steel grade, this pipe undergoes precise manufacturing processes to ensure durability, reliability, and resistance to high-pressure conditions. The pipe is often used in a wide range of applications, including fluid transmission, industrial machinery, and other heavy-duty systems.

Product Advantages

Materials

Steel Grade:

- E235+N

Material Properties:

- E235+Nsteel offers good strength and ductility, ensuring the pipe can withstand high pressures and provide long-term reliability in demanding environments.

- The NBK (normalized, bright)finish gives the pipe an enhanced surface quality, improving corrosion resistance and reducing friction in hydraulic systems.

International Standards

- EN 10305-4: Steel tubes for hydraulic and pneumatic systems.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

- High Pressure Resistance: Designed to withstand high internal pressure, ideal for hydraulic and pneumatic systems.

- Precision Manufacturing: The pipe is cold drawn to ensure accurate dimensions and smooth surfaces.

- Durable Surface Finish: The NBK(normalized, bright) treatment enhances the pipe’s resistance to corrosion and improves its overall mechanical properties.

- Corrosion Resistance: The bright surface finish reduces the risk of rust and corrosion, enhancing the pipe’s lifespan.

- Reliability: Made from high-quality E235+Nsteel, ensuring the pipe can handle demanding environments.

Surface Finish

- NBK (Normalized, Bright):

- The pipe undergoes NBK treatment, which normalizes the steel to relieve internal stresses and gives the pipe a smooth, bright finish. This treatment improves both corrosion resistance and surface quality, which is critical for high-pressure applications.

Specifications

| Parameter | Details |

| Standard | EN 10305-4 |

| Steel Grade | E235+N |

| Surface Finish | Normalized, Bright (NBK) |

| Applications | Hydraulic Systems, Pneumatic Systems, Industrial Equipment |

Dimensional Specifications

| Outer Diameter (mm) | Wall Thickness (mm) | Length (m) |

| 6 – 50 | 1.0 – 10.0 | 6.0 (Customizable) |

Production Process

- Cold Drawing: The steel pipe is drawn at room temperature, allowing for precision dimensions and a smooth, high-quality finish.

- Normalization (NBK Treatment): The pipe undergoes a normalization process to relieve internal stresses and to improve its mechanical properties.

- Bright Surface Finishing: The NBK treatmentensures a bright and smooth surface, enhancing both corrosion resistance and appearance.

- Quality Control: Rigorous quality checks are performed, including dimensional inspections, pressure testing, and non-destructive testing (NDT) to ensure the pipe meets all required standards.

Applications

- Hydraulic Systems: Used for high-pressure fluid transmission in hydraulic systems, such as pumps, valves, and cylinders.

- Pneumatic Systems: Suitable for applications requiring high-pressure resistance and precise fluid control.

- Industrial Equipment: Used in industrial machinery and equipment requiring high-performance steel pipes for fluid transmission.

- Automotive Industry: Applied in hydraulic systems within automotive components, including brake systems and power steering.

- Construction & Mining: Suitable for heavy-duty machinery in construction and mining, where high-pressure hydraulic systems are essential.

Why Choose EN 10305-4 E235+N High Pressure Steel Pipe??

- High Pressure Performance: Built to handle high-pressure conditions, ensuring reliable fluid transmission.

- Precision and Durability: Cold-drawn for precise dimensions and durability, with enhanced surface finish for long-lasting performance.

- Corrosion Resistance: The NBK treatmentimproves the pipe’s resistance to corrosion, ensuring it performs reliably in harsh environments.

- Versatile Applications: Ideal for a range of industries, including hydraulics, pneumatics, and automotive systems, providing a durable solution for high-pressure needs.