EN 10305-4 Equivalent ASTM Hydraulic Steel Pipe

Product Description

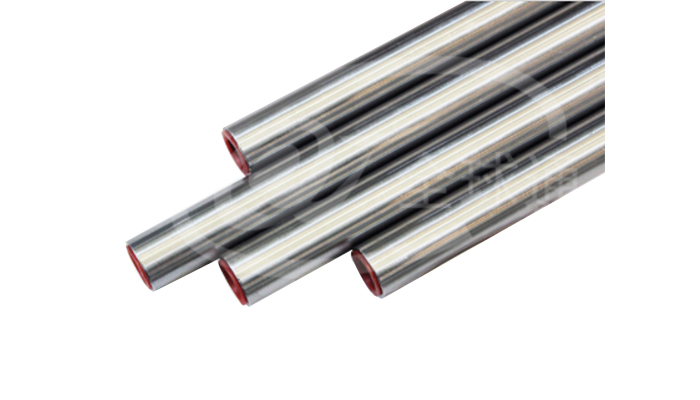

he EN 10305-4 Equivalent ASTM Hydraulic Steel Pipe is a high-precision cold-drawn seamless steel pipe designed for hydraulic and pneumatic systems. It is manufactured to meet both EN 10305-4 and equivalent ASTM standards, ensuring exceptional dimensional accuracy, mechanical strength, and corrosion resistance. These pipes are suitable for high-pressure fluid transmission in various industrial applications, offering reliable and long-lasting performance.

Product Advantages

Materials

- Steel Grades:

- EN Standard: E235, E355

- Material Characteristics:

- High tensile strength

- Good toughness and ductility

- Excellent corrosion resistance with additional surface treatments

International Standards

-

- EN 10305-4: Seamless cold-drawn steel tubes for hydraulic and pneumatic power systems.

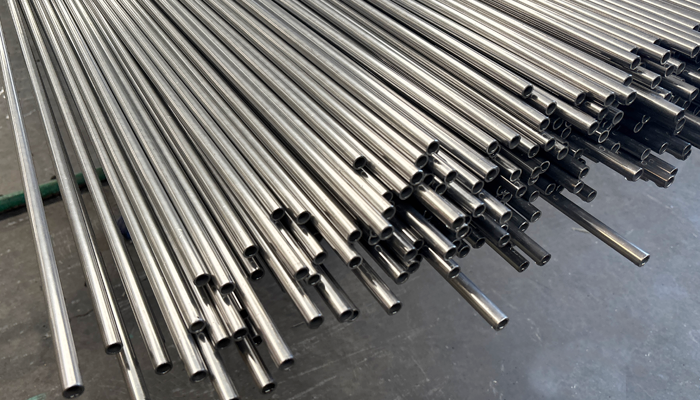

Dimension

General Specifications

| Parameter | Details |

| Standards | EN 10305-4 |

| Steel Grades | E235, E355 |

| Surface Treatment | Galvanized, Phosphated |

| Pressure Rating | Suitable for high-pressure hydraulic applications |

Hydraulic Steel Tube Sizes Specifications

| Outer Diameter (mm) | Wall Thickness (mm) | Length (m) |

| 6 – 120 | 1.0 – 10.0 | Standard: 6m (customizable) |

Features

- High Pressure Resistance: Designed to handle high-pressure hydraulic fluid transmission.

- Superior Dimensional Accuracy: Ensures consistent fluid flow and easy assembly in hydraulic systems.

- Corrosion Protection: Available with surface treatments like galvanization, phosphating, or black oxidation.

- Smooth Inner Surface: Reduces pressure loss and minimizes wear and tear on hydraulic components.

- Customizable Options: Sizes, lengths, and surface finishes can be tailored to specific requirements.

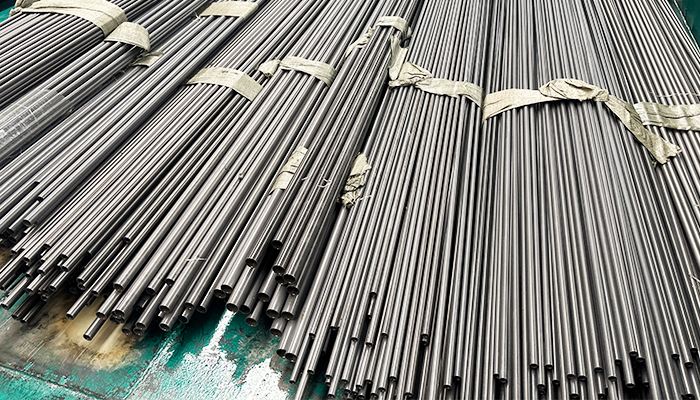

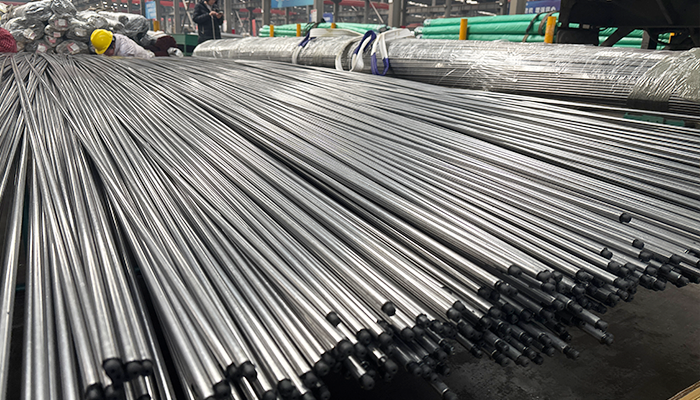

Production Process

- Cold Drawing: Ensures precise dimensions and smooth surface finishes.

- Normalizing or Annealing: Enhances material uniformity and mechanical properties.

- Surface Treatment: Optional treatments like galvanization, phosphating, or black oxidation improve corrosion resistance.

- Quality Inspection: Pipes undergo rigorous testing, including pressure testing, dimensional checks, and non-destructive testing (NDT), to ensure compliance with international standards.

Applications

- Hydraulic Systems: Ideal for hydraulic cylinders, lines, and components in heavy machinery and industrial equipment.

- Pneumatic Systems: Suitable for compressed air transmission in automation systems.

- Automotive: Commonly used in power steering, braking systems, and fuel injection systems.

- Oil and Gas: Used for high-pressure fluid transport in offshore and onshore environments.

- Construction and Agriculture Machinery: Ensures smooth operation of excavators, loaders, and tractors.

Why Choose EN 10305-4 Equivalent ASTM Hydraulic Steel Pipe?

- Dual compliance with EN and ASTM standards for global applications.

- High durability and pressure resistance for demanding environments.

- Customizable to suit specific system requirements.

- Smooth inner surface for optimized fluid flow efficiency.