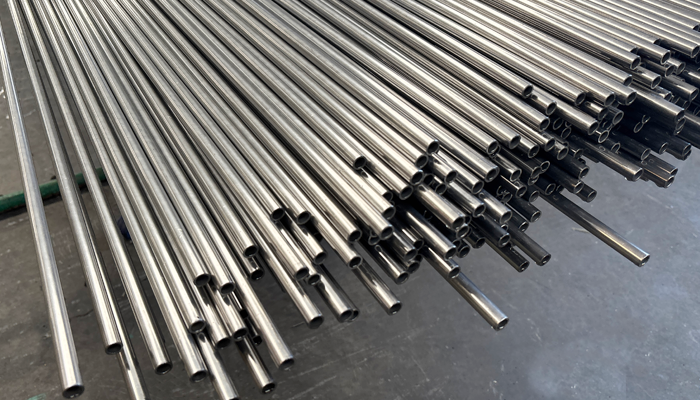

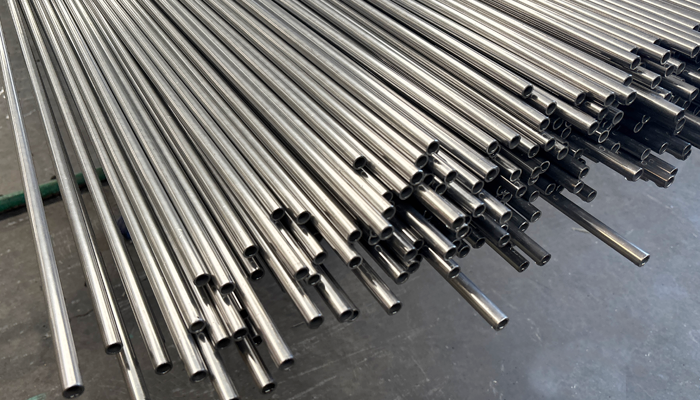

EN 10305-4 Hydraulic Steel Pipe Suppliers

Product Description

EN 10305-4 Hydraulic Steel Pipes are precision-made pipes designed for hydraulic systems. These pipes are manufactured from high-quality steel and conform to international standards, providing reliable performance in demanding applications. They are commonly used in high-pressure hydraulic systems, including machinery, automotive, and industrial applications. The pipes are available in a variety of sizes and specifications to meet customer requirements, ensuring a perfect fit for various hydraulic applications.

Product Advantages

Material

- EN 10305-4 hydraulic pipes are typically made from carbon steel such as E235 or E355, which are known for their excellent mechanical properties. These steels offer a good combination of strength, formability, and weldability, ensuring durability and performance in hydraulic systems. The material is treated to meet specific performance requirements for high-pressure conditions.

International Standards:

- EN 10305-4: European standard for welded and seamless steel tubes for hydraulic and pneumatic systems.

- DIN 2391: German standard for precision steel tubes for hydraulic systems.

Dimension

Features

-

-

- High Strength: The steel used provides excellent tensile and yield strength, ensuring durability under high pressure.

- Seamless Construction: These pipes are manufactured using a seamless method, which eliminates weak points typically found in welded pipes, ensuring better performance under pressure.

- Precision Manufacturing: Pipes are made with strict tolerances, ensuring precise dimensions and smooth surfaces, which enhances flow and minimizes resistance in hydraulic systems.

- Corrosion Resistance: Steel pipes are treated with protective coatings such as zinc plating to resist corrosion, improving their longevity and performance in harsh environments.

Surface:

- Smooth Finish: The inside and outside surfaces of the pipes are smooth, which reduces fluid friction and enhances flow efficiency in hydraulic systems.

- Corrosion Protection: Pipes are typically coated with anti-corrosion oils to protect against rust during storage and transportation. Further treatments like phosphating or zinc plating can be applied for added protection against corrosion.

-

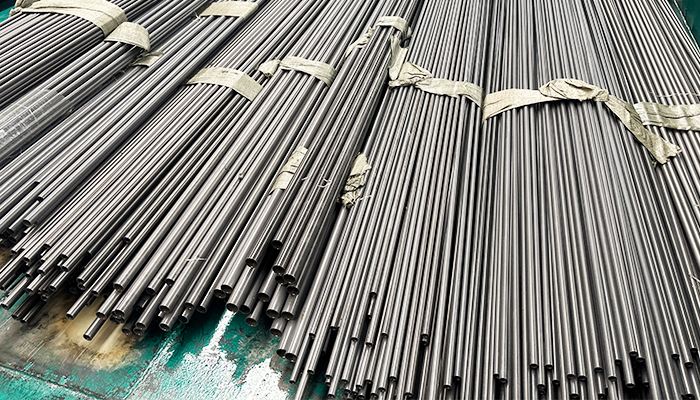

Specifications

| Specification | Details |

| Material | E235, E355 (Carbon Steel) |

| Standard | EN 10305-4, DIN 2391 |

| Delivery Condition | Cold Drawn, Annealed, Zinc Plated |

| Surface Treatment | Anti-corrosion oil, Zinc Coating |

| Manufacturing Process | Cold Drawing, Seamless Manufacturing |

Dimensions:

| Size Range | Details |

| Outer Diameter (OD) | 4 mm to 120 mm |

| Wall Thickness (WT) | 0.5 mm to 10 mm |

| Length | Standard: 6 meters (Customizable) |

Manufacturing Process

- Cold Drawing: The steel is drawn through a die to achieve the desired dimensions and improve the surface finish.

- Heat Treatment: After cold drawing, pipes undergo heat treatment processes such as annealing to relieve internal stresses and improve material properties.

- Surface Treatment: Anti-corrosion coatings such as zinc plating or phosphating are applied to prevent rust and corrosion.

- Testing and Inspection: The pipes are rigorously tested for pressure resistance, dimensional accuracy, and surface integrity.

Applications

- Hydraulic Systems: Primarily used in hydraulic machinery and industrial systems to transfer fluids under high pressure.

- Automotive Industry: For hydraulic applications in vehicles, including brake systems and steering mechanisms.

- Construction Equipment: Used in construction machinery such as excavators, loaders, and cranes.

- Industrial Machinery: For use in various industrial systems requiring fluid transmission under pressure, such as manufacturing equipment and assembly lines.

- Aerospace and Military: Applied in systems requiring high strength and precision for fluid transmission in demanding environments.