How To Choose A Precision Steel Tube For Hydraulic?

-

2022-11-05

2022-11-05

-

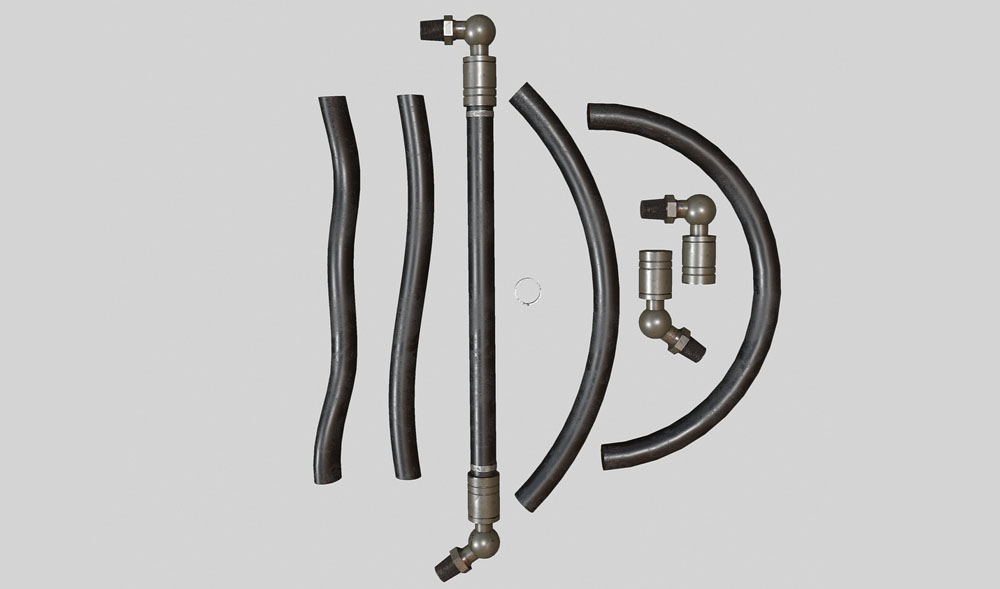

Hydraulic cylinders are an important part of any hydraulic system. These devices are used to produce a linear force in response to a fluid pressure input. The force produced is directly proportional to the pressure input. These cylinders can be divided into two main types: displacement and pressure. Pressure cylinders operate on a relatively small amount of fluid that is contained within the cylinder, allowing it to pressurize and discharge with ease. Displacement cylinders, on the other hand, move large amounts of fluid between chambers of the cylinder in order to create a desired output force. Both of these types have their own individual uses, but different applications may favor one over another depending on the specific needs of the design and use case for which they’re being designed. In this article, we will discuss all you need to know about choosing precision steel tube for hydraulic applications, including types of steel tubes available and considerations when using them in your application.

Types of steel tube for hydraulic applications

When choosing a precision steel tube for hydraulic applications, it’s important to know the various options that are available. This will allow you to find the best fit for your application based on your specific needs. Below is a breakdown of the most common types of precision steel tubing used in hydraulic applications: – Alloy steel tube – Alloy steel is the most common type of steel used in precision steel tubing. It typically has high strength and ductility, making it an excellent choice in standardized hydraulic applications. Alloy steel is also very cost effective and easy to machine. It’s available in a wide range of strengths and compositions, allowing it to be customized to fit a wide range of applications. The most common alloy used in precision steel tubing is alloy 600. – Carbon Steel Tube – Carbon steel precision steel tubing is often used in high pressure environments requiring high strength. This will typically be used in heavy-duty applications that require a high level of durability and higher operating pressures than alloy steel can withstand. Carbon steel precision steel tubing is generally less expensive than alloy tubing, making it a good choice when cost is a factor.

Determining the type of precision steel tube for your application

The type of precision steel tube you choose for your application will depend largely on the specific needs of your design. For example, if you’ll be operating your hydraulic system at high pressures or at a high temperature, you’ll likely want to choose a carbon steel tube over an alloy steel tube. While alloy steel is generally more flexible and easy to work with, it doesn’t have the same strength at higher operating temperatures as carbon steel. Below are some other factors you may want to consider when choosing the type of precision steel tube for your application: – Strength required – The strength of the steel tube you choose will depend on the amount of pressure and force you’ll be putting on it. For example, if you’ll be using your hydraulic cylinder to lift heavy loads, you’ll need a stronger cylinder than you would if you’re using it to open a door. – Operating temperature – The operating temperature of your hydraulic system will have a large impact on the type of steel tube you choose. While an alloy steel tube may be easier to work with when designing your system, a carbon steel tube will be able to withstand higher temperatures. This is particularly important if your system will be operating at or near its max temperature.

What are the most important considerations when selecting a steel tube?

The type of steel tube you choose will depend on your specific design, but there are a few key considerations to keep in mind when choosing the right steel tube for your application. These include: – Pressure – The maximum operating pressure of the system will have a significant impact on which tube you use. This is because the thickness of the precision steel tube will depend on the pressure it’s designed to withstand. For example, a 1/2” OD precision steel tube that is rated for 100 psi can easily be found at most steel suppliers. – Temperature – The type of precision steel tube you choose will also depend on the temperature it’s designed to withstand. This is because the internal diameter increases as the temperature inside the tube increases. For example, a 1/2” OD precision steel tube that is rated for 300° F can only be found at a few steel suppliers. – Material Grade – When selecting a type of steel tube, it’s also important to consider the material grade of the tube. This refers to the percentage of carbon found in the alloy. The higher the grade of carbon, the stronger the tube will be. For example, a 1/2” OD precision steel tube that is rated for 300 psi can be found in both ASTM A-36 and ASTM A-53. Both of these grades are commonly used in hydraulic systems.

Types of Steel Tubes for Hydraulic Applications

As we’ve discussed, the type of precision steel tube you choose for your application will depend on a number of factors. Below is a breakdown of the most common types of steel tubes used in hydraulic applications. – Alloy Steel Tube – Alloy steel precision steel tubes are typically used in applications that require a high strength and durability. These tubes are commonly used in heavy-duty lifting applications due to their high lifting capacity. – Carbon Steel Tube – Carbon steel precision steel tubes are often used in high pressure applications. They are generally considered a high-strength steel tube that can withstand high operating pressures.

Stainless Steel Precision Tubes For Hydraulic Applications

Stainless steel precision steel tubes are generally used in applications where corrosive chemicals are present. For example, they’re often used in the medical and pharmaceutical industries. Stainless steel tubes have excellent resistance to corrosion and also have a high tensile strength. This tube is often used in applications that have a high pressure, such as hydraulic press cylinders. However, it’s important to note that stainless steel precision steel tubes are not recommended for high-pressure hydraulic systems. This is because stainless steel tubing has a relatively low yield strength compared to other types of precision steel tubes.

Nickel-Copper Alloy Precision Steel Tubes For Hydraulic Applications

Nickel-copper alloy precision steel tubes are widely used in many industries due to their ability to withstand high pressure. They are commonly used in hydraulic systems due to their ability to withstand high temperatures and are suitable for use in both high-pressure and high-temperature applications. They are considered a high-strength steel tube, making them suitable for use in a wide range of applications. They also have excellent corrosion resistance, making them an excellent choice in corrosive applications.

Copper Alloy Precision Steel Tubes For Hydraulic Applications

Copper alloy precision steel tubes are an excellent choice for applications where corrosion resistance is important. For example, they’re often used in the medical and pharmaceutical industries. They have excellent resistance to corrosion and also have a high tensile strength. However, they do have a low yield strength when compared to other types of steel tubes. This means they are generally not suitable for hydraulic systems that operate at high pressures. However, they are often used in hydraulic systems that operate at low pressures, such as those found in hydraulic brakes and clutches.

Conclusion

There are many different types of precision steel tubes available for hydraulic applications. However, before choosing which tube is best for your application, it’s important to consider the type of system you’re designing, the operating pressure, and the operating temperature. With a better understanding of the different types of steel tubes, you’ll be able to find the best fit for your application and be sure that your system will operate as intended for years to come.