How To Choose The Right Black Steel Pipe For Hydraulics?

-

2022-10-11

2022-10-11

-

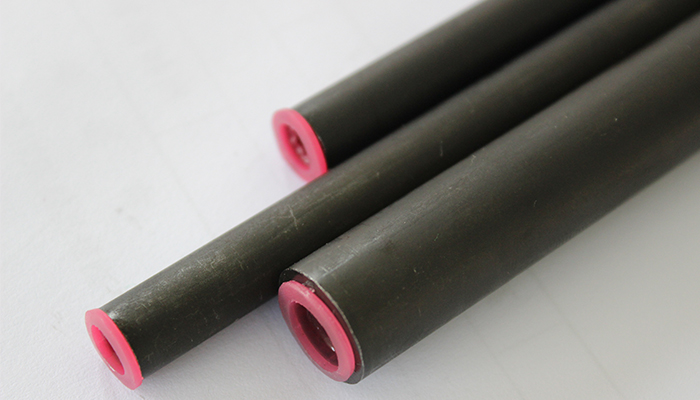

Black steel pipe for hydraulics is used in many industries and applications, from robotics to construction. The hydraulic pipe is a crucial part of any hydraulic system because it transfers fluid from one point to another. It is the most common type of pipe used in hydraulics because it has the right combination of strength, weight, and cost.

It is made from carbon steel that has been treated with a black oxide coating. When you’ll be working with hydraulics, choosing the right one can be tricky because there are so many different types on the market.

Fortunately, with some expert advice, you’ll be able to make the best choice for your specific needs. Before you buy a black steel pipe, it’s helpful to understand exactly what it can do for your hydraulics system and how to pick the perfect one for your needs.

What Is Black Steel Pipe?

Black steel pipe is also known as carbon steel pipe because it is made from carbon steel that has been black oxidized. This is a process that makes the steel stronger while also protecting it from corrosion, wear, and abrasion.

Black steel pipe is available in different wall thicknesses and diameters, with the most common being wall thicknesses of either 3/16, 1/4, 5/16, or 3/8 inches, and diameters of 1/2, 3/4, 1, 11/2, 2, 3, and 4 inches.

It’s important to understand that a black steel pipe isn’t the same as a black iron pipe. Black iron pipe is a softer, much cheaper pipe that is no longer widely used due to the high risk of corrosion. Black steel pipe is the most popular type of pipe used in hydraulic applications.

Strength And Durability Of Black Steel Pipe

Carbon steel is a highly durable metal that is used widely in hydraulic and plumbing applications because of its strength and durability. The black oxide coating also makes it easy to clean and resistant to corrosion, abrasion, and wear.

There are different wall thicknesses for black steel pipe, which means the amount of material used for the walls of the pipe. The thicknesses are measured in either inches or millimeters. The thicker the walls, the more durable the pipe will be, though this will also increase the cost.

Black steel pipe comes in a variety of diameters, which means the circumference of the pipe. The larger the diameter, the more fluid it can hold. Generally, the diameter of the pipe should be around 5-10% of the flow rate.

Diameter And Wall Thickness Of Black Steel Pipe

When choosing the right black steel pipe, the diameter and wall thickness are the two main things to consider. The diameter of the pipe should be no more than 10% of the flow rate.

The wall thickness of the pipe should be approximately 25% of the flow rate. For example, for a hydraulic system that operates at 10,000 pounds per square inch, the diameter of the pipe should be between 1/2 and 5 inches, and the wall thickness of the pipe should be between 4/10 and 2/10 inches.

Coated Vs. Uncoated Black Steel Pipe

There are a few different types of black steel pipe available, including uncoated and coated black steel pipe. Uncoated black steel pipe is more common, while coated black steel pipe is more expensive.

The coating on coated black steel pipe is designed to protect the pipe from corrosion and abrasion, which is especially important in environments that are salty, sandy, or wet. It also makes the black steel pipe easier to clean and more sanitary.

Coated black steel pipe is more expensive because of the extra process required to apply the coating.

Durability For Different Uses Of Black Steel Pipe

Certain types of black steel pipe are better suited for certain uses. For example, if you’ll be using the black steel pipe for boiler feed water, you’ll need to use a pipe that’s made from a corrosion-resistant material because it will be in contact with salt water.

If you’ll be using black steel pipe for hydraulic applications, then any type of pipe is suitable.

Pipe Fittings for Black Steel Pipe

Pipe fittings are used to connect different pipes together, and they come in a variety of sizes and materials. When choosing a fitting, you’ll need to decide if you want it to be male or female and what type of pipe you’ll be connecting the fitting to.

For example, if you want to connect a black steel pipe to another pipe, then you’ll need to choose a fitting that can connect to the black steel pipe.

It has many different types of couplings, unions, bends, nipples, and reducers, tees, crosses, and valves.

Summing up

Black steel pipe is a common, versatile type of pipe that is commonly used in hydraulic applications. The pipe is made from carbon steel that has been treated with a black oxide coating to make it corrosion-resistant.

The pipe diameter should be no more than 10% of the flow rate, and the wall thickness of the pipe should be approximately 25% of the flow rate.

There are a few different types of black steel pipe available, including uncoated and coated black steel pipe. Depending on the type of black steel pipe you choose, you may need to use a specific type of fitting.