Hydraulic Piping and Hydraulic Piping System

Product Description

- Purpose: Hydraulic piping is designed to convey liquid fluids between hydraulic components, fittings, valves, flanges, and other tools.

- Materials: Typically made from materials such as E355 (ST 52.4) or E235 (ST 37.4), each with distinct chemical compositions that influence their working pressure capabilities.

- Standards: Manufactured according to standards like DIN 2391/C (DIN EN 10305-1) and DIN 2445/2 (DIN EN 10305-4), ensuring precision and quality in hydraulic applications.

- Surface Treatments: Options include phosphating for hydraulic line pipes and electro-galvanizing, with blue or yellow chromating available upon request, enhancing corrosion resistance.

- Mechanical Properties: Utilizing higher quality materials allows for reduced wall thickness and weight while maintaining the same working pressure, optimizing system efficiency.

- Applications: Essential in hydraulic systems for efficient fluid transmission between various components, ensuring optimal performance across different industries.

Types of Hydraulic Pipes

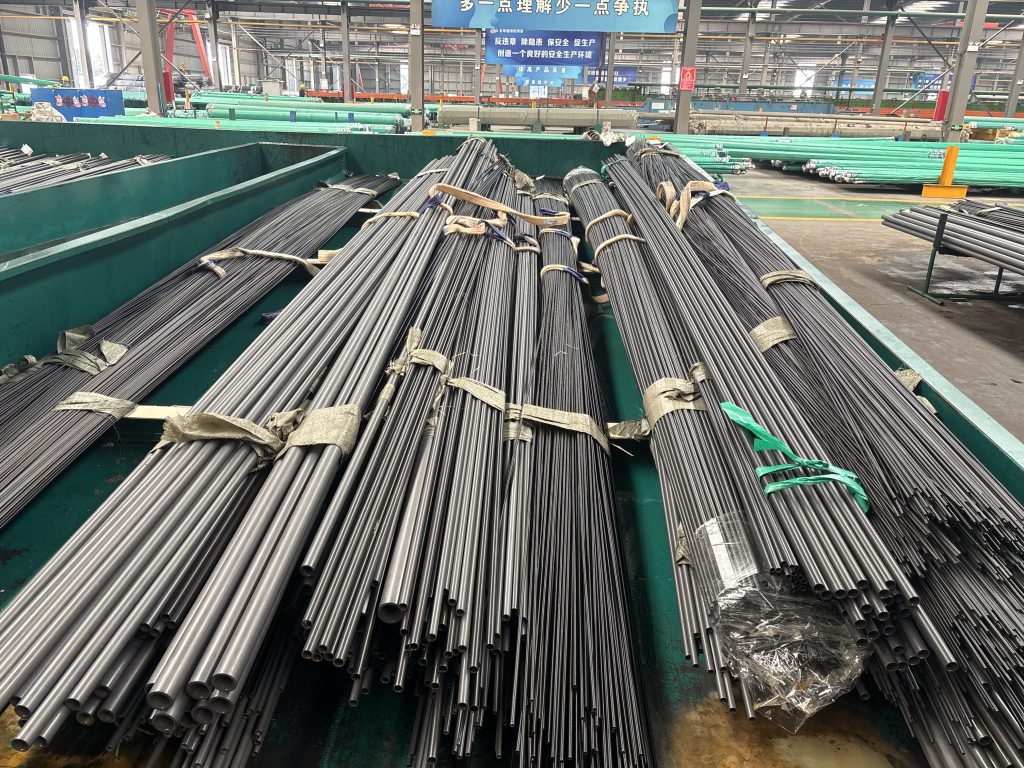

1.Steel Hydraulic Pipes

- Description: Made from carbon steel or stainless steel, these are widely used for high-pressure hydraulic systems.

- Types:

- Seamless Steel Pipes: With no welds, ideal for high-pressure applications.

- Welded Steel Pipes: Manufactured with a longitudinal weld, suitable for moderate pressure systems.

- Common Standards: DIN 2391, EN 10305-4, ASTM A519.

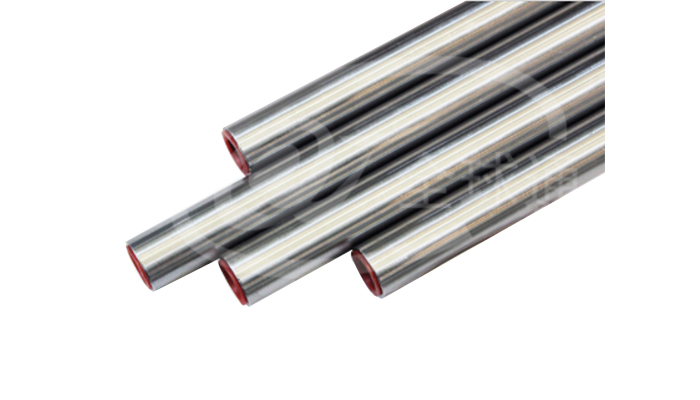

2.Stainless Steel Hydraulic Pipes

- Description: Resistant to corrosion, suitable for harsh environments or applications with aggressive fluids.

- Applications: Marine, chemical, and food processing industries.

- Surface Finish: Often polished for smooth fluid flow.

3.Copper Hydraulic Pipes

- Description: Excellent thermal conductivity and corrosion resistance, but limited to low-pressure applications.

- Applications: Used in small hydraulic equipment or refrigeration systems.

4. Galvanized Hydraulic Pipes

- Description: Carbon steel pipes coated with a zinc layer for corrosion protection.

- Applications: Outdoor and marine environments where rust resistance is critical.

5. Phosphated Hydraulic Pipes

- Description: Steel pipes with a phosphated coating to improve corrosion resistance and lubrication.

- Applications: Widely used in industrial hydraulic systems.6. Heat-Treated Hydraulic Pipes

- Description: Pipes normalized or annealed to enhance strength and ductility.

- Applications: High-pressure and high-temperature hydraulic systems.

What is the difference between Hydraulic Piping System and Hydraulic Piping?

Example:

“We use seamless steel hydraulic piping with a zinc-coated surface for corrosion resistance.”

This emphasizes the specific type and material properties of the pipes.

- Hydraulic Piping System

- Definition: A hydraulic piping system refers to the complete fluid transmission system comprising multiple hydraulic pipes, connectors (such as fittings, flanges, and valves), pumps, hydraulic reservoirs, and more. It focuses on the design, structure, and functionality of the entire system.

- Characteristics:

- Emphasizes how the entire system operates, including the design and optimization of fluid paths.

- Involves how pipes interact and integrate with other hydraulic components (pumps, valves, cylinders).

- Focuses on overall performance, such as flow control, pressure stability, and efficiency.

Example:

“The hydraulic piping system is designed to ensure efficient fluid transmission across all components in the industrial press machine.”

This describes the design and overall functionality of the system.

Summary

- Hydraulic Piping: Focuses more on the attributes and specifications of individual pipes, which are components of the system.

- Hydraulic Piping System: Refers to the complete assembly of pipes and other components, including design, installation, and operation.

In simple terms, Hydraulic Piping is a part of the Hydraulic Piping System, while the system represents the larger whole.