Non-Welded Hydraulic Piping Systems

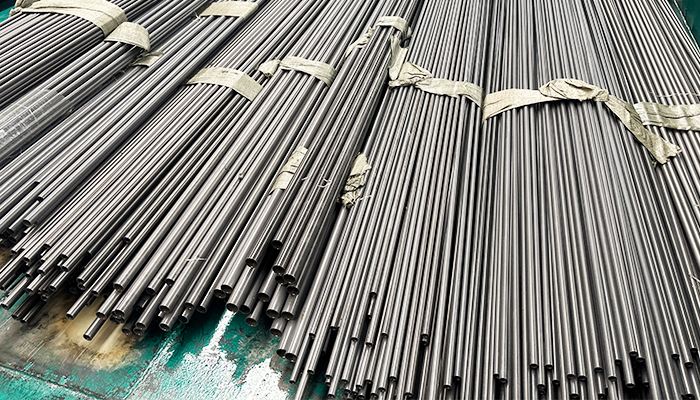

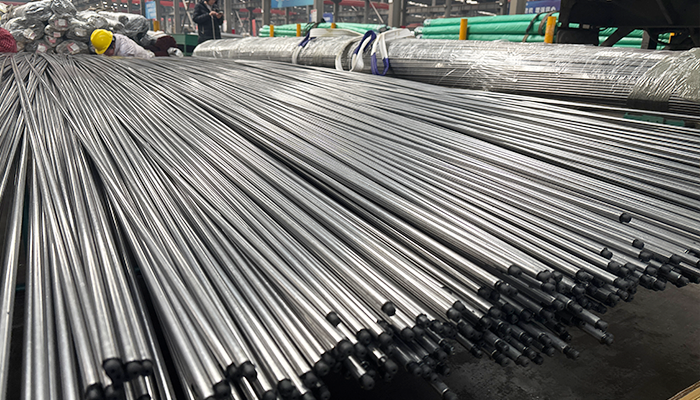

Non-welded hydraulic piping systems are a reliable and efficient solution for the transportation of hydraulic fluids under high pressure. These systems are designed to withstand the demanding requirements of modern hydraulic machinery while offering increased strength, safety, and flexibility compared to traditional welded piping solutions. Made from high-quality seamless pipes, they ensure minimal risk of leaks and are ideal for fluid transmission in industries such as construction, automotive, and manufacturing.

Product Advantages

- Non-welded hydraulic piping systems are typically made from high-strength carbon steel, stainless steel, or alloy steel. The material is chosen based on the application’s pressure requirements, corrosion resistance, and temperature considerations. Stainless steel is often used in environments that require superior corrosion resistance, while carbon steel provides excellent strength and durability at an affordable cost.

International Standards:

- DIN 2391: Specifies the standard for precision seamless tubes.

- EN 10305-4: Defines the technical requirements for seamless cold-drawn precision steel tubes used in hydraulic systems.

These standards ensure that the hydraulic piping systems meet global safety and performance benchmarks.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

- Seamless Construction: The non-welded design eliminates the risk of welding defects and improves the overall strength and durability of the piping system.

- High Pressure Resistance: Capable of handling high-pressure fluids, making them suitable for heavy-duty hydraulic applications.

- Excellent Fluid Flow: Smooth inner surfaces reduce friction, allowing for better fluid flow and reducing the chance of pressure drops.

- Corrosion Resistance: Available in materials like stainless steel for enhanced resistance to corrosion, especially in harsh environments.

- Durability: High-quality materials and manufacturing ensure long-lasting performance with minimal maintenance.

Surface Treatment:

The surface of non-welded hydraulic pipes can undergo various treatments to enhance corrosion resistance and durability. Common treatments include:

-

- Galvanizing: Provides excellent protection against rust.

- Phosphating: Improves surface adhesion and reduces wear.

- Passivation: Enhances corrosion resistance, especially for stainless steel.

| Specification | Details |

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Standard | DIN 2391, EN 10305-4, ASTM A106 |

| Delivery Condition | +N (Normalised), Cold Drawn |

| Surface Treatment | Galvanized, Phosphated, Passivated |

Dimensions

| Dimension | Range |

|---|---|

| Outer Diameter (OD) | 6 mm – 200 mm |

| Wall Thickness (WT) | 1 mm – 15 mm |

| Length | 6 meters (custom lengths available) |

- Cold Drawing: The pipes are produced through a cold-drawing process to ensure high precision and smooth surface finish.

- Heat Treatment: The pipes are heat-treated to relieve internal stresses and improve mechanical properties.

- Surface Cleaning: Pipes are cleaned of any scale and impurities to enhance the quality and performance of the piping systems.

Applications

-

- Non-welded hydraulic piping systems are used in various industries where high pressure and reliability are essential:

- Construction Machinery: Hydraulic systems in excavators, cranes, and loaders.

- Automotive Industry: Power steering, brake systems, and hydraulic lifts.

- Manufacturing: Injection molding machines, industrial presses, and more.

- Agriculture: Hydraulic systems for tractors and harvesters.

- Oil & Gas: Fluid transport in exploration and production operations.

- Non-welded hydraulic piping systems are used in various industries where high pressure and reliability are essential: