Why Precision Galvanized Steel Tube Is The Best Material For Your Pipe Needs

-

2022-09-16

2022-09-16

-

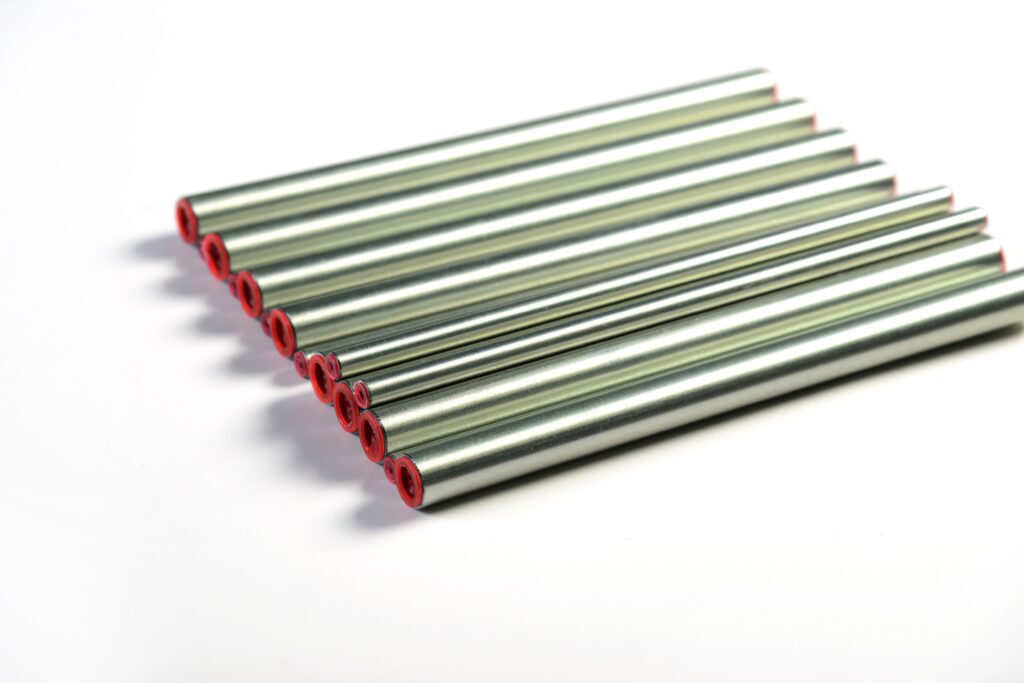

Precision Galvanized Steel Tube is a great material for piping needs. Its corrosion-resistant properties make it the ideal choice for keeping your water systems in top shape. It’s also cost-effective, easy to work with, and readily available from many different suppliers.

Galvanized steel is the third most used material for making pipes, behind iron and cement. There are many things to consider when choosing the right material for your pipe needs, but one of the most important things you need to think about is how well that particular type of material will stand up over time.

Galvanized steel has several advantages over other options, including its durability, texture, and cost efficiency.

What Is Precision Galvanized Steel Tube?

Galvanized steel is steel that has been coated with zinc. This process of galvanization is used to protect the metal from corrosion and rust. When steel is galvanized, it is dipped into a bath of molten zinc.

This process coats the steel with zinc, which is a non-ferrous metal. It also creates a barrier that prevents corrosion. Zinc is a naturally occurring element that can be found in a variety of soils. When it’s mined, it is then refined and turned into galvanized steel.

This is one of the most common materials used when creating piping systems, like those you’d find in underground water supply lines. When it comes to piping, you have a choice between two types of galvanized steel: hot-dipped galvanized steel and electro galvanized steel.

Hot-dipped galvanized steel is the most common option. It’s made by submerging the steel in molten zinc, which causes the metal to harden and form a coating around the steel.

Electrogalvanized steel is made using an electrical current to create an electrochemical reaction. This reaction creates a zinc coating around the steel that is very similar to the process used for hot-dipped galvanized steel.

Why Is Galvanized Steel The Best Material For Pipes?

Galvanized steel is the best material for pipes for several reasons. First, it is corrosion-resistant. There are many different types of corrosion, but whatever type it is, you can be sure that galvanized steel will stay strong and prevent the corrosion from spreading.

Iron is another good material for pipes, but it is not corrosion-resistant. If you’re near a body of water, galvanized steel is the better option since it can stand up to corrosion from saltwater. Galvanized steel is also strong and durable.

It can withstand a lot of wear and tear and is likely to last longer than other materials that are used to create piping systems. Galvanized steel is also easy to work with and easy to install. It can be cut, bent and joined together with relative ease, making it easier to install in certain areas that might be difficult to access.

Pros Of Galvanized Steel For Pipes:

There are many benefits associated with galvanized steel for pipes. It is the most economical and cost-effective option when it comes to piping. It is easily accessible and can be found at most supply stores.

Galvanized steel for piping is also easy to install, which makes it ideal for do-it-yourself projects. Plus, it is durable, corrosion-resistant, and can withstand a lot of wear and tear.

If you’re in need of a material that is easy to work with and can stand up to a lot of wear and tear, then galvanized steel is the best option for your piping needs.

Cons Of Galvanized Steel For Pipes:

There are a couple of drawbacks to galvanized steel for pipes. The first is that it is difficult to weld. If you’re looking to create a long piping system, it might not be the best option because you won’t be able to connect it together in one continuous piece.

The second drawback of galvanized steel for piping is that it is loud when you’re installing it. The sound of the hammering and banging can be loud, so be sure to wear ear protection and work in an area that has soundproofing.

Should You Use Galvanized Steel For Piping?

Yes! Galvanized steel is an excellent choice for piping. You’ll get many years of reliable service from this material, so it’s a great investment. It is easy to work with and can be joined together in continuous pieces. Plus, it is moderately priced, which makes it an economical choice as well.

Galvanized steel is an excellent choice for piping needs. If you’re looking for a material that can stand up to a lot of wear and tear, is easy to work with, and won’t break the bank, then it’s the best option for you.

Plus, you’ll be able to install it in a variety of areas, including near bodies of water that contain saltwater.

How to Install Galvanized Steel Pipe?

When installing Galvanized Tube, it’s important to remember that you’ll need to use a thread sealant. This is because galvanized steel is not as strong as other materials and can be prone to leakage if you don’t seal it properly.

Galvanized steel is also very heavy, so you’ll want to make sure that you’re working in an area that has plenty of room. Set up some cones and barriers to mark off the area and prevent anyone from getting hurt.

Make sure that you have all of your tools and equipment at hand before you start working. This will prevent any unnecessary delays while you’re in the middle of your project. You’ll also want to make sure that you’re wearing proper safety gear.

This includes safety goggles, gloves, ear protection, and any other items that your workplace safety manual recommends.

Wrapping Up:

Galvanized steel is a great choice for piping needs. It is the most cost-effective option, is easy to work with, and can be used for continuous pieces. It is also the most corrosion-resistant of all the piping materials.

No matter which piping material you choose, be sure to use a thread sealant to prevent any leakage, and make sure you’re following all appropriate safety procedures.