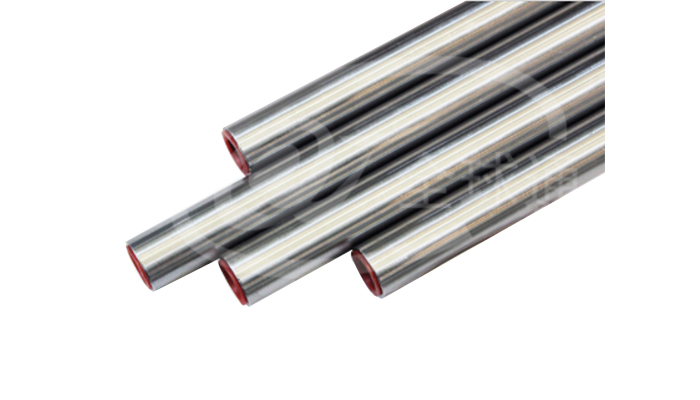

SAE J524 Bright Precision Carbon Steel Pipe

Product Name: SAE J524 Bright Precision Carbon Steel Pipe

Standard: EN10305-4 (DIN2445/2), EN10305-1 (DIN2391), ASTM A179

Steel grade: E235 (ST35 ST37.4), E355 (ST52 ST52.4)

Size: OD: 4-120mm

WT: 0.5-10mm

Length: Fixed 6m or as your request

Surface treatment: bright – anti-corrosion treatment after NBK

Delivery condition: +N (NBK) normalized under a controlled atmosphere

Delivery time: 15-45 days, according to the quantity you need and whether the goods are in stock

Special pipe material: API pipe, thick-walled pipe

Outer diameter: 10 – 1000 mm

Thickness: 1.4 – 14mm

Standard: ASTM

Length: 12M, 6m, 6.4M, 3-12m

Certificates: API, CE, SASO, SABS, KS, JIS, GS, ISO9001

Grade: Carbon Steel

Tolerance: ±1%, ±1%

Processing services: welding, punching, cutting, bending, uncoiling

Oiled or unoiled: Lightly oiled

If you have any questions about product quality, usage, etc., please contact us: global steeltube

Product Advantages

-

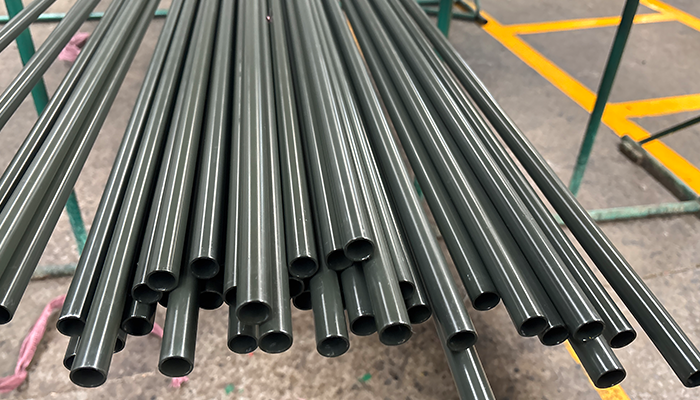

No oxide layer

No oxide layer on both sides of tube

-

Surface

High precision, smooth surface

-

No crack

No crack during flaring and flattening

-

Anti-rust

Anti-rust on inside and outside

-

Cold bending

Cold bending without deformation

Cold drawn / cold rolled: High dimensional accuracy, excellent internal and external wall finish

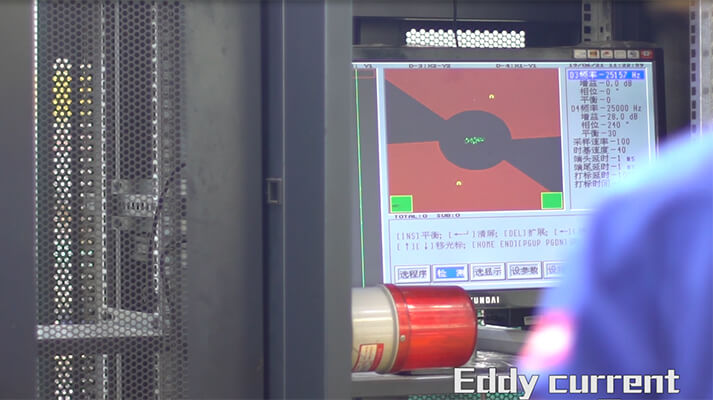

Eddy current testing: Each steel pipe is tested by eddy current flaw detection to ensure product quality

Anaerobic bright heat treatment (NBK): When the seamless steel pipe is annealed, vacuum is applied and ammonia-decomposed nitrogen and hydrogen are injected for protection heating, heat preservation and cooling. It maintains the original rolling accuracy and smoothness of the steel pipe, and has excellent mechanical properties and metallographic structure.

Cleaning: We use high-pressure cleaning equipment and ultrasonic cleaning equipment to clean steel pipes. The inner and outer walls are coated with anti-rust oil, and both ends are sealed to prevent dust.

| OD | Thickness(m m) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | ||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 10*1 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Steel grade | C

max. |

Si

max. |

Mn

max. |

P

max. |

S

max. |

Total

min. |

|

| Name | Number | ||||||

| E215 | 1.0212 | 0.10 | 0.05 | 0.7 | 0.025 | 0.015 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.025 | 0.015 | — |

| E355 | 1.0580 | 0.22 | 0.55 | 1.6 | 0.025 | 0.015 | — |

| Outer Diameter | Allowable tolerance | Special tolerance | |||||

| GB/T3639 | DIN2391 | OD | WT | ||||

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm | |||

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm | |||

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm | |||

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm | |||

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm | |||

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm | |||

| Steel grade | Yield strength | Tensile strength | Elongation | ||||

| Name | Number | RH | Rm | A | |||

| min. | min. | min. | |||||

| MPa | MPa | % | |||||

| E215 | 1.0212 | 215 | 290 to 430 | 30 | |||

| E235 | 1.0308 | 235 | 340 to 480 | 25 | |||

| E355 | 1.0580 | 355 | 490 to 630 | 22 | |||

FAQ:

1. Do you offer payment plans?

Yes, we offer payment plans with various term length options. View details of our payment plans.

2. How should I buy steel from you? How to choose the right one for me?

Yes, we offer payment plans with various term length options. View details of our payment plans.

3. What is the delivery time?

Usually, we have pipe fittings in stock and can be delivered within 10 days. Other products will ship within 20 days of receiving your payment.

4. Can I get a sample?

Yes, samples are available for your use. But you need to pay for samples and shipping by yourself. Also, please confirm with us before paying the sample fee and shipping cost.

5. How do you ship the goods?

We usually ship the goods by sea or air express (DHL UPS FedEx). If you would like to ship by other means, please notify us in advance. If your quantity is large enough, we can arrange our truck or train to ship directly to you from our factory. We also offer delivery service if required.

6. What are the payment terms?

For large orders, we accept T/T (Bank Transfer), Western Union and Paypal payment terms, but do not accept small orders, which should be paid by T/T only for security reasons.

If you have any questions about product quality, usage, etc., please contact us: global steeltube