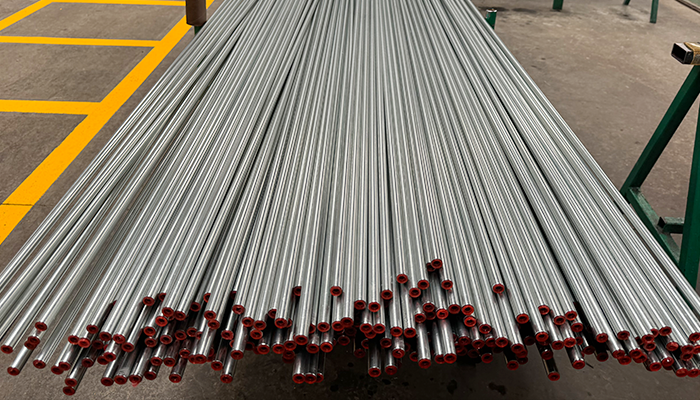

Seamless Precision Carbon Steel Tubes

Precision Carbon Steel Tubes are high-quality, cold-drawn seamless tubes designed for applications requiring tight tolerances and superior surface finish. These tubes are normalized under a controlled atmosphere (+N or NBK condition) to ensure consistent mechanical properties and dimensional accuracy. They are commonly used in hydraulic and pneumatic power systems, automotive industries, and engineering machinery.

Product Advantages

These tubes conform to the following international standards:

- EN 10305-4: Steel tubes for precision applications; technical delivery conditions.

- DIN 2391: Seamless precision steel tubes.

- ASTM A179: Standard specification for seamless cold-drawn low-carbon steel heat-exchanger and condenser tubes.

- SAE J524: Seamless low-carbon steel tubing suitable for bending and flaring.

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

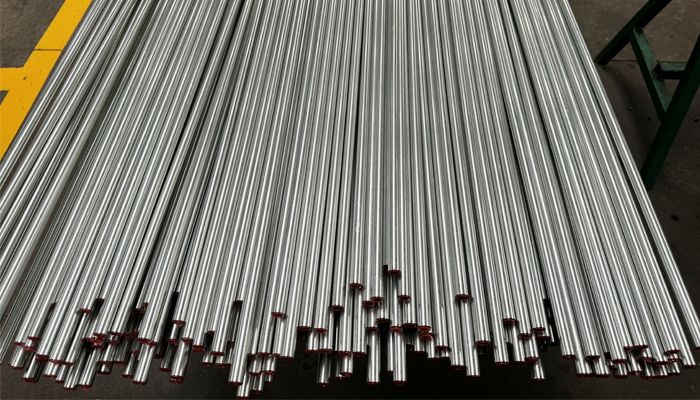

- High Dimensional Accuracy: Achieved through cold drawing processes, ensuring precise outer diameter (OD) and wall thickness (WT).

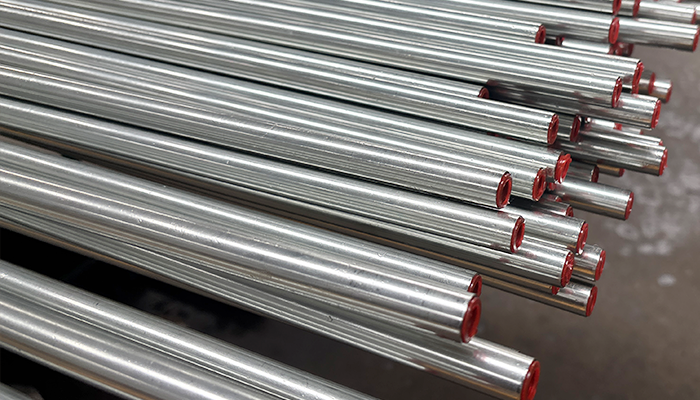

- Superior Surface Quality: Smooth internal and external surfaces, reducing friction and enhancing performance.

- Excellent Mechanical Properties: Normalized under controlled atmosphere to attain uniform mechanical characteristics.

- Corrosion Resistance: Available with various surface treatments, such as galvanization and phosphating, to enhance durability.

Below is a table summarizing the typical specifications:

| Parameter | Details |

| Outer Diameter (OD) | 4mm – 120mm |

| Wall Thickness (WT) | 0.5mm – 10mm |

| Length | Standard length of 6 meters; customizable upon request |

| Steel Grades | E235 (ST35, ST37.4), E355 (ST52, ST52.4) |

| Surface Treatments | Galvanized (zinc coating of 8 to 12μm), phosphated, bright finish |

| Delivery Condition | +N (NBK) – normalized under a controlled atmosphere |

| Shape | Round |

| Protection | Anti-rust oil applied on inner and outer surfaces; plastic covers at both ends |

The production of Precision Carbon Steel Tubes involves the following steps:

- Perforation: Creating a hollow shell from solid steel billets.

- Pickling and Phosphating: Cleaning the surface and applying a phosphate layer to facilitate cold drawing.

- Cold Drawing/Cold Rolling: Reducing the diameter and wall thickness to achieve desired dimensions and surface finish.

- Annealing: Normalizing under a controlled atmosphere (+N or NBK) to attain uniform mechanical properties.

- Surface Treatment: Applying coatings such as galvanization or phosphating for corrosion resistance.

- Protection: Applying anti-rust oil on inner and outer surfaces and capping ends with plastic covers.

Applications

Precision Carbon Steel Tubes are utilized in various sectors, including:

- Hydraulic and Pneumatic Systems: Used in hydraulic cylinders, pneumatic cylinders, and fluid lines.

- Automotive Industry: Employed in fuel lines, brake lines, and structural components.

- Engineering Machinery: Applied in construction equipment, agricultural machinery, and heavy-duty vehicles.