Seamless Precision Steel Tubes: Application Specific

-

2023-07-18

2023-07-18

-

Seamless precision steel tubes are an essential part of various industries. Incorporating exceptional accuracy, strength, and dependability, they are the go-to option for many projects. Their property as a reliable solution is much sought after in automotive, energy, construction, and manufacturing sectors alike. In this post, we will delve into the multiple usages and explain why seamless precision steel tubes are key to successful operations in these industries.

Manufacturer Spotlight: Xuzhou Global Precision Steel Tube Co., Ltd:

When it comes to manufacturing seamless precision steel tubes, one name that stands out is Xuzhou Global Precision Steel Tube Co., Ltd. With their unwavering commitment to quality and innovation, Xuzhou Global has earned a reputation as a leading manufacturer in the industry. Their state-of-the-art production facilities, advanced technologies, and stringent quality control measures ensure that their seamless precision steel tubes meet the highest standards. Whether it’s custom requirements or large-scale orders, Xuzhou Global delivers products that exceed customer expectations.

Automotive Industry: Driving Performance and Safety

In the automotive industry, where precision and reliability are of utmost importance, seamless precision steel tubes find extensive use. These tubes are widely employed in the production of fuel injection systems, braking systems, hydraulic cylinders, and exhaust systems, among others. The seamless nature of these tubes ensures a smooth flow of fluids and gases, optimizing the performance and efficiency of these crucial automotive components. Additionally, their high strength and resistance to corrosion make them ideal for withstanding the harsh conditions encountered on the road, ensuring enhanced safety and longevity of vehicles.

Manufacturing and Machinery: Enhancing Precision and Performance

In the manufacturing sector, precision is paramount, and seamless precision steel tubes enable the production of high-quality machinery and equipment. These tubes are extensively used in the manufacturing of hydraulic systems, pneumatic cylinders, precision instruments, and machine tools. The seamless nature of these tubes ensures uninterrupted fluid or gas flow, enhancing the precision and reliability of these critical components. Moreover, their dimensional accuracy and uniformity facilitate seamless integration within complex manufacturing processes, contributing to overall operational efficiency and productivity.

Tips for Choosing Seamless Precision Steel Tubes

1. Understanding the Application Requirements

The first step in selecting seamless precision steel tubes is to thoroughly understand the specific application requirements. Consider factors such as temperature, pressure, corrosion resistance, mechanical properties, and dimensional accuracy. Each application may demand distinct characteristics, and identifying these criteria will help narrow down the options and ensure a tailored solution.

2. Assessing Material and Quality

The quality of seamless precision steel tubes directly impacts their performance and longevity. Look for tubes made from high-quality materials with exceptional chemical composition and mechanical properties. Manufacturers like Xuzhou Global Precision Steel Tube Co., Ltd., often provide detailed material specifications to aid in the selection process. Third-party certifications, such as ISO 9001, indicate a commitment to quality and consistency in production.

3. Dimensional Precision and Tolerance

Seamless precision steel tubes are known for their tight dimensional tolerances. Precise dimensions are essential, especially when the tubes will be used in critical applications. Review the dimensional specifications provided by the manufacturer to ensure they meet the required tolerances. Opt for a manufacturer with a reputation for consistently delivering tubes with superior dimensional precision.

4. Surface Finish and Coating

The surface finish of seamless precision steel tubes influences their suitability for particular applications. A smooth and defect-free surface reduces friction and enhances performance. Additionally, some applications may require specific coatings or finishes to enhance corrosion resistance or to ensure compatibility with other components. Evaluate the available surface finish options and coatings offered by the manufacturer.

5. Testing and Inspection

Reliable manufacturers conduct rigorous testing and inspection procedures to verify the quality of their seamless precision steel tubes. Look for certifications such as ISO 9001, ISO 14001, or IATF 16949, which demonstrate the manufacturer’s commitment to quality control. Xuzhou Global Precision Steel Tube Co., Ltd. has a reputation for maintaining stringent quality assurance processes and providing customers with consistently high-quality products.

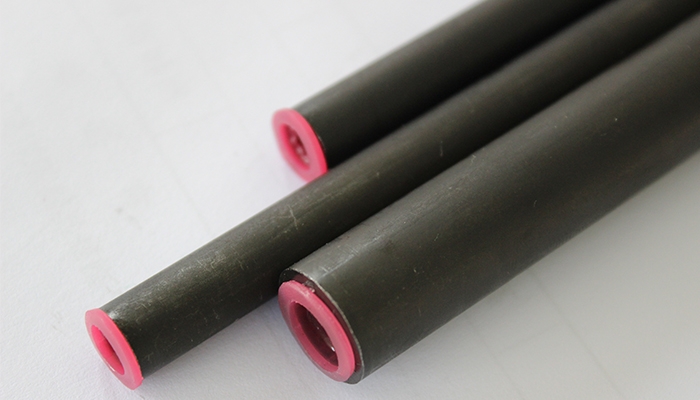

Seamless Precision Steel Tubes: DIN/EN Black Phosphated Precision Seamless Steel Tubes for Sale

1. Feature: Black Phosphated Coating

One notable feature of these precision steel tubes is the black phosphated coating applied on both sides of the pipe. This coating serves several purposes. Firstly, it enhances the overall appearance of the tubes, giving them a sleek and polished look. The black phosphated coating is delicate, ensuring a high level of lubricity that promotes smooth operation.

Additionally, the uniform color of the coating adds to the tubes’ aesthetic appeal. However, the benefits go beyond appearance. The black phosphated coating provides excellent anti-corrosion and anti-rust properties, making these tubes ideal for demanding environments where protection against rust is essential.

2. Technical Characteristics: Standards, Grades, Heat Treatment, and Surface Treatment

The seamless precision steel tubes adhere to international standards, including DIN2391/C (EN10305-1), EN10305-4 (DIN2445), and SAE J524. These standards ensure that the tubes meet the required specifications and quality benchmarks for various applications.

The tubes are available in different grades to cater to specific needs. The grades include E235 (ST35, ST37.4), E255 (ST45), and E355 (ST52), providing options for a wide range of engineering and industrial applications.

In terms of heat treatment, the tubes undergo NBK (+N) normalization, ensuring optimal mechanical properties and improved performance.

The surface treatment of these precision steel tubes is bright as cold drawn. This surface finish not only adds to their visual appeal but also contributes to their overall durability and resistance to corrosion.

3. Delivery Conditions and Packaging

The tubes are delivered in NBK (+N) condition, ensuring that they are normalized and ready for immediate use.

For packaging, the tubes are sealed at both ends with plastic caps and then bundled with plastic film and woven bags. Each bundle weighs a maximum of 1000kgs, providing convenience and ease of handling during transportation. The length of the tubes is fixed at 6m but can be customized according to the customer’s requirements.

4. Application: Wide Range of Industries

The DIN/EN black phosphated precision seamless steel tubes find extensive application in various industries. They are commonly used in engineering machinery, ships, precision machinery, hydraulic and pneumatic systems, and more. The unique phosphating surface treatment makes these tubes especially suitable for painting or spray treatments.

When the tubes are painted, the phosphated surface ensures strong adhesion, resulting in excellent and beautiful paint finishes. Furthermore, the phosphating treatment significantly enhances the tubes’ resistance to rust, providing added longevity and protection in harsh environments.

Conclusion:

Seamless precision steel tubes are an integral part of numerous industries, offering exceptional performance and reliability. Whether it’s the automotive, energy, construction, or manufacturing sectors, these tubes play a crucial role in enhancing efficiency, durability, and safety. As highlighted by the manufacturer spotlight on Xuzhou Global Precision Steel Tube Co., Ltd, industry leaders strive to produce top-quality seamless precision steel tubes that meet the diverse needs of their customers. With their unmatched precision and reliability, these tubes continue to drive innovation and progress across industries, making them an indispensable component in modern engineering and manufacturing practices.