Seamless Steel Hydraulic Lines

Product Description

International Standards

- DIN 2391: German standard for precision seamless steel tubes, especially in hydraulic applications.

- EN 10305: European standard for seamless steel tubes for hydraulic and pneumatic systems.

- ISO 9001: Global quality management system standard ensuring consistency and quality of manufacturing.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

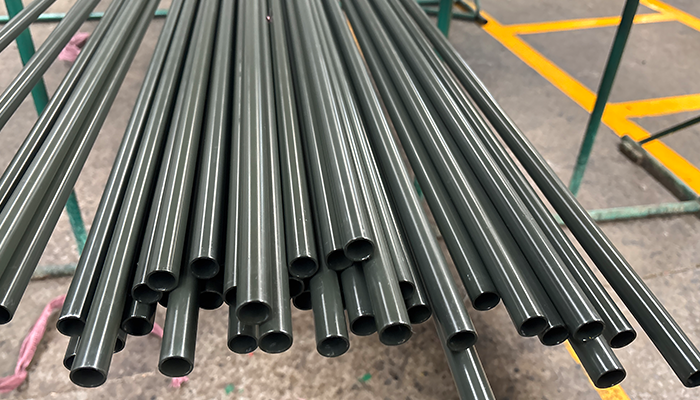

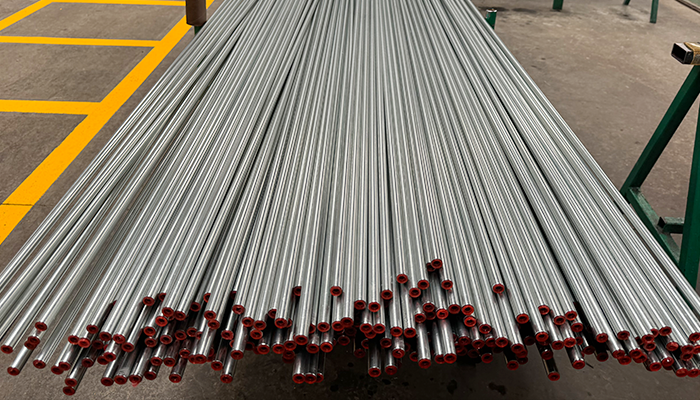

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

-

-

- Seamless Construction: The absence of welds or seams ensures the tube has no weak points, providing better resistance to pressure and reducing the risk of failure.

- High Pressure Resistance: Designed for high-pressure hydraulic systems, the tubes can withstand substantial internal pressure and provide a stable, reliable flow of hydraulic fluid.

- Corrosion Resistance: Surface treatments like phosphating or galvanizing improve corrosion resistance, making the tubes suitable for outdoor, marine, and industrial applications.

- Precision & Accuracy: The cold drawing process ensures tight dimensional tolerances, improving consistency and performance in hydraulic systems.

- Versatility: Suitable for various industries, from automotive to aerospace, oil & gas, and manufacturing, where high-performance hydraulic systems are needed.

-

Main Applications

- Hydraulic Systems in Machinery: Used extensively in construction machinery, manufacturing equipment, and forklifts for fluid transmission and hydraulic power delivery.

- Automotive Industry: Employed in hydraulic brake lines, steering systems, and suspension components for enhanced vehicle performance and safety.

- Aerospace: Used in aircraft hydraulic systems for flight control, landing gear, and other critical functions.

- Oil & Gas: Essential in drilling rigs, pumping systems, and hydraulic equipment for fluid transmission under high pressure in oil and gas extraction processes.

- Marine Applications: Utilized in ships for steering, lifting, and various hydraulic functions in harsh marine environments.

- Agricultural Machinery: Applied in farming machinery such as tractors and harvesters for efficient hydraulic operation.

- Heavy Equipment: Found in mining equipment, excavators, and other heavy-duty machinery requiring robust hydraulic systems for heavy lifting and operation.

Specifications

| Specification | Details |

| Material | Carbon Steel, Stainless Steel |

| Outer Diameter (OD) | 6mm – 500mm |

| Wall Thickness (WT) | 1mm – 20mm |

| Length | Standard Length: 6m (Custom lengths available) |

| Surface Treatment | Phosphated, Galvanized, Painted, Oiled |

| Pressure Rating | High Pressure (up to 1500 bar) |

| Standards | DIN 2391, EN 10305 |

Manufacturing Process

- Extrusion & Piercing: The process begins with extrusion from billets, followed by piercing to create a hollow tube.

- Cold Drawing: The tube undergoes cold drawing to reduce its diameter and achieve precise wall thickness, ensuring dimensional accuracy and high surface finish.

- Heat Treatment: Controlled heat treatment such as annealing or normalizing is applied to enhance the strength and toughness of the steel, especially for high-pressure applications.

- Surface Treatment: Various surface coatings like phosphating, galvanizing, or oil coating are applied to prevent corrosion and improve the durability of the hydraulic lines.

- Cutting & Inspection: The tubes are cut into required lengths and undergo rigorous testing to ensure compliance with dimensional, mechanical, and performance standards.

Fabrication Methods

- Cold Drawing: The seamless tube is drawn through a die to achieve the desired size, ensuring high precision in dimensions and smooth inner and outer surfaces.

- Heat Treatment: Tubes are heat-treated to enhance their strength, ductility, and resistance to fatigue, particularly under high-pressure conditions.

- Surface Coating: Phosphating, galvanizing, or painting is applied to the tube’s surface to improve corrosion resistance, making the tubes ideal for challenging environments.

- Cutting & Bending: Custom length cutting and bending processes are used to shape the tubes according to specific application requirements.