What Are Metal Hydraulic Lines?

-

2022-09-16

2022-09-16

-

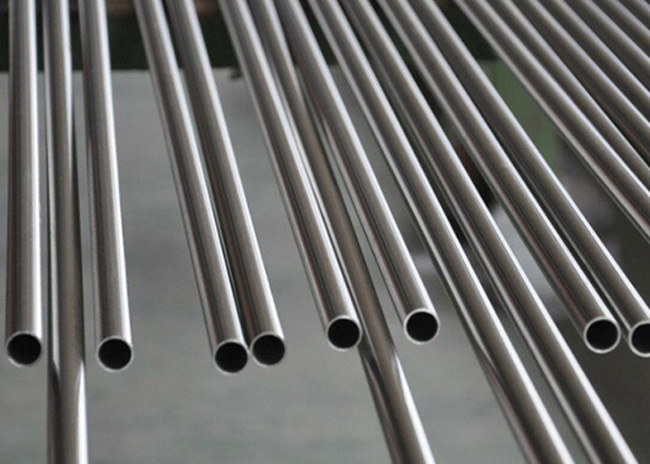

Metal hydraulic lines are tubing that is used for the transmission of hydraulic pressure in a variety of different applications. The lines must be able to withstand high pressures without bursting or leaking.

They are typically made from an oil-resistant synthetic material, but may also be metal in some applications. The most common types of hydraulic lines include those that are double-ended, uni-directional, and triplex.

If you work with hydraulic systems, it’s important to understand what hydraulic lines are and how they operate in different situations.

Hydraulic lines are essential components in any hydraulic system, so if you have one available, take time now to review this article before continuing on your repair journey.

What Are Metal Hydraulic Lines?

We use the metal hydraulic line for the transmission of hydraulic pressure in a variety of different applications.

Usually, we make hydraulic lines from oil-resistant synthetic materials.

We can find them in many kinds of machinery, including hydraulic lifts, cranes, and industrial presses.

Hydraulic lines connect to pumps or other pressure sources and must be able to withstand high pressures without bursting or leaking.

What Are Metal Hydraulic Lines?

There are several different methods of making metal hydraulic lines, but the most common is to start with a flat metal sheet and shape it into a tube.

Common metal alloys used in hydraulic lines include stainless steel, alloy steel, carbon steel, Inconel, and other superalloys. While the exact materials used will vary depending on the application, the metal will usually be an alloy of iron, chromium, nickel, and/or other elements.

What Is The Working Pressure Of A Metal Hydraulic Line?

We rate its working pressure, or maximum allowable working pressure (MAWP) through a unit called pounds per square inch.

For example, if a metal hydraulic line has a working pressure rating of 2,000 psi, it is capable of handling up to 2,000 pounds of pressure per square inch. Many metal hydraulic lines have the pressure rating stamped somewhere on the outside of the tube.

If the metal hydraulic line doesn’t have a pressure rating stamped on it, you can calculate the working pressure using the formula below:

Pressure rating = Maximum operating pressure / Wall thickness

For example, if you have a metal hydraulic line with a wall thickness of 0.09 inches and a maximum operating pressure of 2,000 psi, the working pressure will be 1,111 psi.

Benefits Of Using Metal Hydraulic Lines:

- Strong and Durable

Metal hydraulic lines are some of the strongest and most durable lines available. They can withstand pressures of up to 350,000 psi and are therefore ideal for transmitting high-pressure fluids.

- Resistant to Corrosion

Most metal hydraulic lines are highly resistant to corrosion, which makes them ideal for use in applications with high-pressure fluids.

- Excellent Heat Transfer

They have excellent heat transfer properties, which makes them suitable for use in a wide variety of different applications.

- Good Conductivity

Most have a fairly high electrical conductivity, making them suitable for many electrical applications.

Metal Hydraulic Line: Disadvantages and Problems:

- Expensive

They are generally more expensive than synthetic lines.

- More Susceptible to Wear

Compared to synthetic hydraulic lines, metal hydraulic lines are more susceptible to wear and tear due to contact with abrasive materials.

- Proper Installation

Also, they require careful installation to prevent corrosion, leaks, and other problems.

Summing Up:

In conclusion, hydraulic lines are Passivated Tube that we use to transmit hydraulic pressure in a variety of different applications. They must be able to withstand high pressures without bursting or leaking.

Tare essential components in any hydraulic system, so if you have one available, take time now to review this article before continuing on your repair journey.